How Mobility Engineers can build a Creative Mindset

Introduction

Global Automotive industry currently is at the crossroads – the future is being shaped up by technology and business model disruptions across. The manufacturing of the vehicles is being transformed by digital technologies and the transformation is popularly referred to as Industry 4.0. The emerging automotive industry is fueled by the convergence of fast-growing technologies in products, multi-disciplinary collaboration, leveraging cloud computing power, design of connected and intelligent machines, cybersecurity features, Internet of things (IoT) etc. While the industry is fast evolving, the external environment is disrupted by economic uncertainty, stringent regulations, higher customer demands and shorter product life cycles. These changes are radical in nature and are compelling the automotive engineers to build new skills, capabilities, and a creative mindset.

Future Skills for Mobility Engineer 2030

The skills that mobility engineers have to build to prepare themselves for the future of automotive industry are broadly of three types – Expertise (core engineering foundation), Integration and Growth skills. The foundation is set by engineering domain knowledge spread across mechanical engineering, electrical and electronics engineering and computer programming. The integration skills help the engineers to use their domain knowledge and build products – these include customer orientation, communication, quality management and systems management. For the engineer to excel in his work and steadily grow in his technical career, he / she needs a growth mindset that comprises of innovation mindset, right ethics, intelligent management of risks and ability to learn (learnability). We have described these skills in a series of articles published in this series “Mobility Engineer 2030” [1]. These skills were identified by SAE FISITA through a very detailed research and interviews with mobility experts across industry and academia [2].

The terms “creativity” and “innovation” are often used interchangeably. In the words of Harvard Professor Teresa Amabile, paraphrased by Daniel Goleman, creativity is coming up with new and useful ideas and innovation is the successful implementation of those ideas [3].

Figure 1 – Mobility Engineer 2030 – Future Skills

What is Creative Mindset

There is ample literature describing the role of innovation and creativity in new product development, how to overcome the barriers to creativity and various tools and techniques for engineer to foster their creativity. David Cropley [4] elaborates the linkage of creativity and engineering. Creativity is defined as the ability of an individual to possess and effectively use both convergent and divergent thinking while providing technological solutions. The four product areas where creativity can be exercised are Artefact, Process, System and Service. In specific, the creative process is explained using the seven phases viz. Preparation, Activation, Generation, Illumination, Verification, Communication, Validation. Each of these phases needs specific personal traits in terms of motivation, personal properties and feelings to enable creativity.

One of the proven ways to nurture and develop creativity of engineers is the use of Problem Based Learning (PBL) technique. The technique focusses on applying the current level of knowledge to the problem and gaining knowledge during the process of finding the solution and alternatives. Asking engineers to provide, the one correct answer to a problem as fast as possible, does not contribute towards fostering problem-solving abilities. The engineer’s originality and creativity can be stifled if the emphasis is only on the correct or predefined solution. The learning process should ideally (a) enable engineers to learn how to analyze the problem and (b) share their technical knowledge with team members and learn from each other. Problem-based learning helps engineers to acquire creative thinking skills and professional skills when they work on complex, interdisciplinary, and real-situation problems [5].

Creativity is inhibited by certain cognitive blocks and behaviors. Kazem [6] mentions ten creativity blockers as fear of the unknown, fear of failure, reluctance to exert influence, frustration avoidance, resource myopia, custom bound, reluctance to play, reluctance to let go, impoverished emotional life and over certainty.

How to build a creative mindset

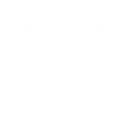

Our paper focuses on six thinking tools to help an engineer to develop a creative mindset. The creative mindset helps him / her to meet the emerging and future needs of the industry. The creative mindset is a necessary ingredient and forms the building blocks of innovation for any organization. This is a necessary but not sufficient condition, as organizations need to create various enablers through systems, processes, structures, and strategy to spur the creative efforts at individual as well as organization level. We use examples from the automotive industry to illustrate the application of each mindset as an effective thinking tool. These attributes are easy to understand and practice. These benefit individual engineers as well the collective organization to develop innovative products and solutions. Figure 2 shows the six-creative mindset as thinking tools.

Figure 2: Creative Mindset Thinking Tools

Creative Mindset 01: Gather Insights

The first step to develop creative mindset is to acquire a keen attitude to observe and inquire into the surrounding and especially from the customer environment. Insights helps to understand the elements which provides power, freedom and control to the customers or users while they are accomplishing their mission. Effective probing and sound observation go beyond what customer expresses (VoC, Voice of Customer) and forms a seed for potential innovation.

It’s worth reminding that customers are on their mission and products are means to accomplish the same more effectively and effortlessly. The insights are generally subtle and can be gathered by probing in the customer environment though set of three simple questions.

- What are the situations, customers are not empowered or excessive human intervention to carry on the mission?

- What are situations, customer is not in control or have excessive or unnecessary control to carry on the mission?

- What are the situations, customers lose freedom or have excessive or unnecessary freedom to carry on the mission?

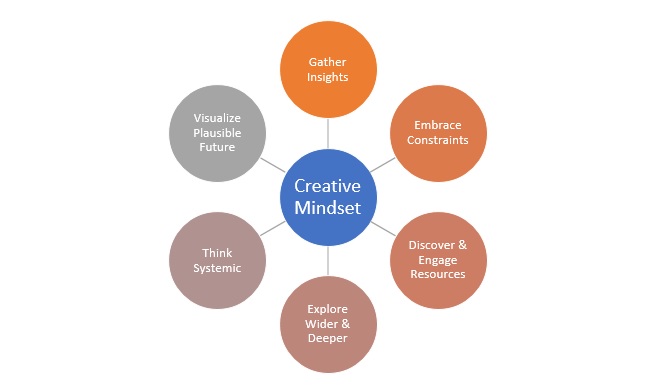

Examples – Parking a vehicle is always a tedious, stressful process for a driver especially in the urban congested areas. The problem is even bigger for wider cars. Although customers or users are used to park cars themselves, self-parking car features readily provides them the freedom to focus more on their core mission. The technology is emerging and is already introduced to market by automotive players like Tesla, Tata, BMW, and Lexus [7].

Figure 3 – Gather Insights – Example self-parking cars [7]

In an excavator, a finer observation shows that the operator moves the bucket at much higher speed while tracking back after unloading. This happens in the environment of projects under the high continuous throughput demand like Mining. High speed tracking the bucket is so natural for operator that it incurs higher fuel penalty as engine revs up to higher speed and operates in an inefficient zone. The back-tracking speed of the bucket can be controlled or limited by internal logic irrespective of operator’s pedal position in every cycle. This solution yield significant fuel economy and reliability benefit. The available literature [8] can also be used to gather insights.

Here are few more examples – Automotive technologies like electronic stability control [9] provides complete vehicle stability in all driving conditions like high-speed cornering, skidding control, traction control and braking control on unfriendly terrains. The technology is established based on the driving behaviors, terrain conditions, vehicle configuration and necessary is driven by direct voice of customer. Self-cleaning filter for the operation in dusty environment where the customer has to otherwise replace air, fuel, oil filters frequently. Self-cleaning filter uses the air to flow in reverse direction at right conditions like when customers are not using the application, to clean the dust and contaminated accumulated [10].

Creative Mindset 02: Embrace Constraints

The constraints are generally perceived as obstacles when we explore new possibilities. However, an optimum level of constraints is desirable and is in fact is a necessary condition for innovation to happen. The very imposition of constraints compels the team to think out of the box and come out with breakthrough ideas. These new ideas are quite different from ideas arising from conventional wisdom or collective experience. The solution is bound to be innovative as it meets all critical customer needs while respecting the constraints posed.

Examples – The Tata Nano vehicle is a well-known product innovation in the Indian automotive industry. The product is developed under tighter constraints of cost to make it affordable while not compromising on internal space, safety, and comfort. The R&D team developed this world class product way back during 2010 and exceeded many global benchmarks. The placement of the engine in the rear, light body, single wiper etc. together makes it a very innovative product [11]

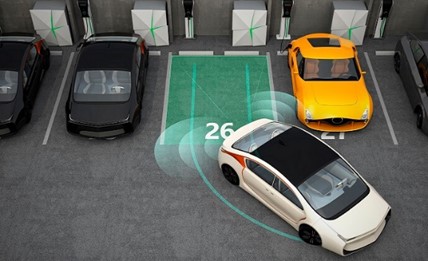

Aviation industry faces tight and stringent constraints on the weight of the aircraft structure and individual component. Boeing has described the developed new material called Metal Microlattice composed of 99% of Air volume which maximizes payload and reduce fuel consumption. The material is said to be worlds’ s lightest material constructed from interconnected hollow tubes, with a wall thickness of just 100 nanometres – 1,000 times thinner than a human hair [12].

Figure 4 – Overcome the constraints – Example Ultra-light metal microlattice [12]

The other examples include the defence application that needs high power density of engines due to tighter space constraints. Opposed Piston, Opposed Cylinder engine (OPOC) provides almost double the power than conventional four stroke diesel engine due to its unique architecture arrangement and corresponding control elements [13]. Indian Mars Mission “Mangalayan” uses the PSLV low power Vehicle by making its journey as hyperbolic gradual trajectory approaching MARS. This idea helped to overcome the constraint posed by the lack of availability of high-power vehicle like GSLV [14].

These are the cases where constraints were imposed by the organization as part of product strategy. However, in other cases, creative mindset needs that team actively discover the underlying and sometimes hidden constraints in the given context. As an example, CNG operated vehicles are quite economical however there is a constraint of lesser number of fuelling stations and thus higher waiting time. Multiple automobiles have implemented dual fuel (gasoline and CNG) engine as technology solution to overcome this constraint and empower customers [15]

Creative Mindset 03: Discover and Engage Resources

Resources is one of the key ingredients for any innovation. Resources are part of the product ecosystem where every resource can interact with the product and thereby influence the functionality and outcome. Resources can be broadly categorized as material, properties, energy, information, people, waste, space and time [16]. Creative mindset needs the active discovery and usage of available resources within or beyond the ecosystem of the product.

The resources can be discovered by drawing ecosystem diagram for the product. Figure 5 shows the ecosystem for an automobile. All the elements of the ecosystem are potential resources available to engage and develop innovative solution.

Figure 5 An Ecosystem of an Automotive Product

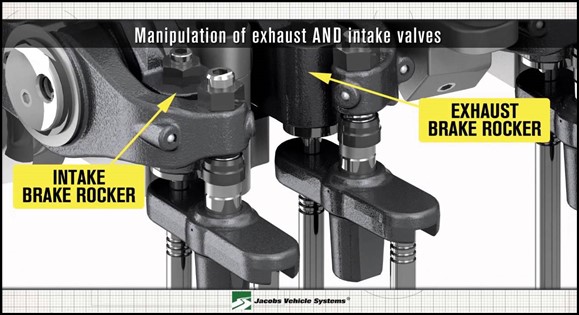

Examples – The fleet owners for heavy duty commercial trucks face recurring maintenance cost of replacing the service brake pads to ensure safety on the roads. The faster and unpredictable wear of brake pads poses higher risks to safety and further adds up to total cost of ownership. Any major improvements to size and material properties of brake pads will significantly increase the initial cost of the product. Most of the heavy-duty trucks now uses concept of Engine Compression Brakes especially after BS-VI norms are implemented in India. The idea revolves around using engine compression work for the purpose of retarding the vehicle [17]. The add on hardware, control algorithm etc. need to be integrated in the system to make it work. Engine is a reliable resource available for braking and thus offers cost effective solution.

Figure 6 – Discover and engage resources – Example Engine compression brake [17]

The concept of connected cars is based on the use of information from surrounding cars and systems as readily available resources. Vehicle to Vehicle communication enables to provide real time information about what is there in the surrounding and coming up around the vehicle. The information is intelligently processed to provide drivers warnings and make real time decision to avoid crash type of situations [18].

Figure 7 – Discover and engage resources – Example Connected cars [18]

The other examples include the use of aircraft wings to store the fuel to minimize the weight of the vehicle, use of ambient air for high-speed vehicles for thermal cooling of mechanical, electrical and electronics equipment’s like engine, alternator, starter motor, batteries, control units etc

Creative Mindset 04: Explore Wider and Deeper

As the products become multidisciplinary, the best possible solution lies in a completely foreign domain. An innovator, with a tendency to stay within his comfort zone of domain knowledge, may miss the optimum solution. The innovators need not necessary learn all the nitty-gritties of other disciplines, but they must develop their ability to collaborate with the right experts beyond their native domain to find out the best possible solutions.

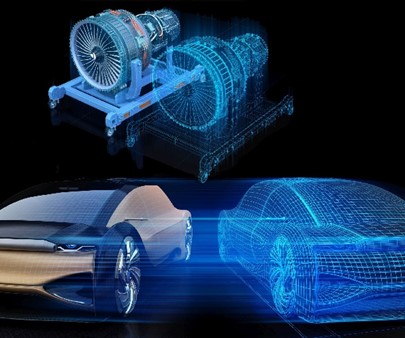

Examples – The reliability of industrial products like excavators, trucks, Tractors, tippers, gensets is of utmost importance. The reliability requirements in terms of zero defect and zero downtime is one of the critical requirements for the market. The conventional approach may suggest revisiting design robustness and improve it through better materials or higher design margins. As material are stretched to their limits, any further improvement can lead to overdesign and sub-optimized performance for aspects like packaging and weight. The potential solution in this case can come from the aerospace industry that uses the concept of Digital Twin coupled with machine learning for predictive analytics. The digital twin is the virtual model of the physical products integrated with multiple sensors used to analyze the health of the system in real time. The processing can predict the potential failures with high accuracy and guide the crew to make proactive decisions [19].

Figure 8 – Explore wider and deeper – Example Digital twin of products [19]

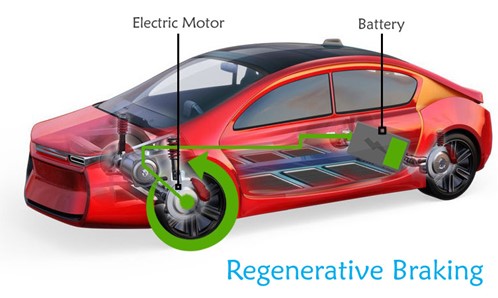

Regenerative braking is quite common in hybrid and electric vehicles [20]. Although it improves the vehicle efficiency, it has its own challenges. A high level of regenerative brake can be detrimental to battery at low SOC stage due to high internal resistance leading to severe heating. Also, the high regenerating force or high currents is not desirable at High SOC due to safety concerns. One approach points to controlling the battery chemistry and corresponding electrode characteristics as part of ongoing research. The most feasible solution in this case may be created at system level rather than at component level. A US patent application [21] uses electronic friction braking along with regeneration braking to strategically control the operation to enhance braking effectiveness while ensuring prolonged battery life.

Figure 9 – Explore wider and deeper – Example Regenerative braking in an electric vehicle (EV) [20]

The other examples include the use of nano additives in lubrication oil to improve the viscosity index at high temperature rather than conventional oil cooling solution, the use of fuel additives to improve the cetane number for better combustion characteristics, the use of battery swapping model at the charging station rather than waiting for longer charging time for electric vehicles [22]

Creative Mindset 05: Think Systemic

The most brilliant ideas sometimes fail to create impact across the value chain of the product. This happens as some or the other element in the system in not conducive or aligned for the idea to manifest its full potential. The system element could be serviceability, manufacturability, availability of fuel or energy source itself. The systemic mindset thus is critical to execute idea from lab to market successfully.

Examples – Electrification of the vehicles promises multiple benefits to customers and environment in terms of better performance, low noise, low emissions, and low carbon footprint. However, a systemic view points out that unless the fast-charging infrastructure is in place, merely bringing more electric vehicles will not create an attractive proposition to the customer. Tesla has created its own charging infrastructure to unleash the full potential of their electric vehicles [23].

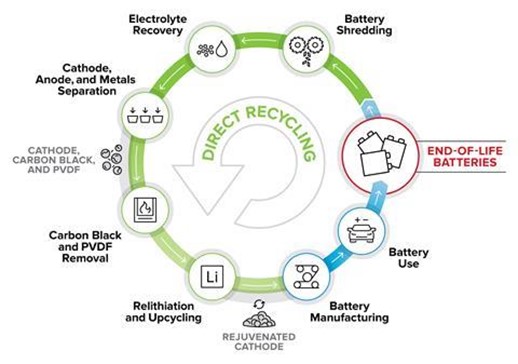

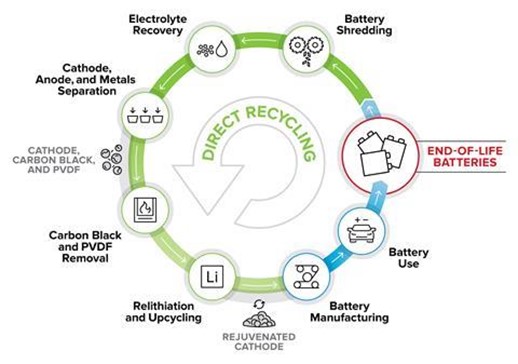

Figure 10 – Think Systemic – Example Creating a Network of fast-charging stations for EVs [23]

The EV battery is witnessing a high rate of technology development for every aspect related to performance, power density, energy density, safety, and life. The systemic view enables us to understand the sustainability aspect for any given technology knowing the fact that improper disposal of materials used in batteries could be detrimental to environment. Unless the materials developed are recyclable or reusable, the technology may become obsolete very soon. This mistake can lead to environmental damage, loss of investments and loss of human efforts. One of the key development trends for EV battery is to make it sustainable by establishing circular economy or value chain around the product [24].

Figure 11 – Think Systemic – Example Circular Economy Model for EV Battery [24]

The other examples include the components like engine Piston, Bearing Housings or Propeller Shafts are overdesigned so that they are re-manufacturable after intended usage over product life. This saves cost and significant carbon footprint for modern organizations [25]. The use of a platform-based architecture for multiple products to standardize key architecture elements. This provides right level of customization, reliable, cost effective products with lower development cycle time [26].

Creative Mindset 06: Visualize Plausible Future

Disruptive Innovations needs a strong orientation towards the future and a vision of how the markets and products are going to look like in near and long-term future. This needs a mindset for breaking core assumptions and sense what lies beyond the horizon. This creates technology push and clear product strategy even under external uncertain conditions. Creative mindset needs the ability to deal with ambiguities associated with an uncertain future. We need an open mind to explore possibilities and accept alternatives. We need a collaborative and interactive way of working to effect various course corrections during idea implementation [27]. The tools like pattern analysis, TRIZ Technology trends and scenario planning can help the engineer to synthesize the vision of the future world and develop an innovation roadmap

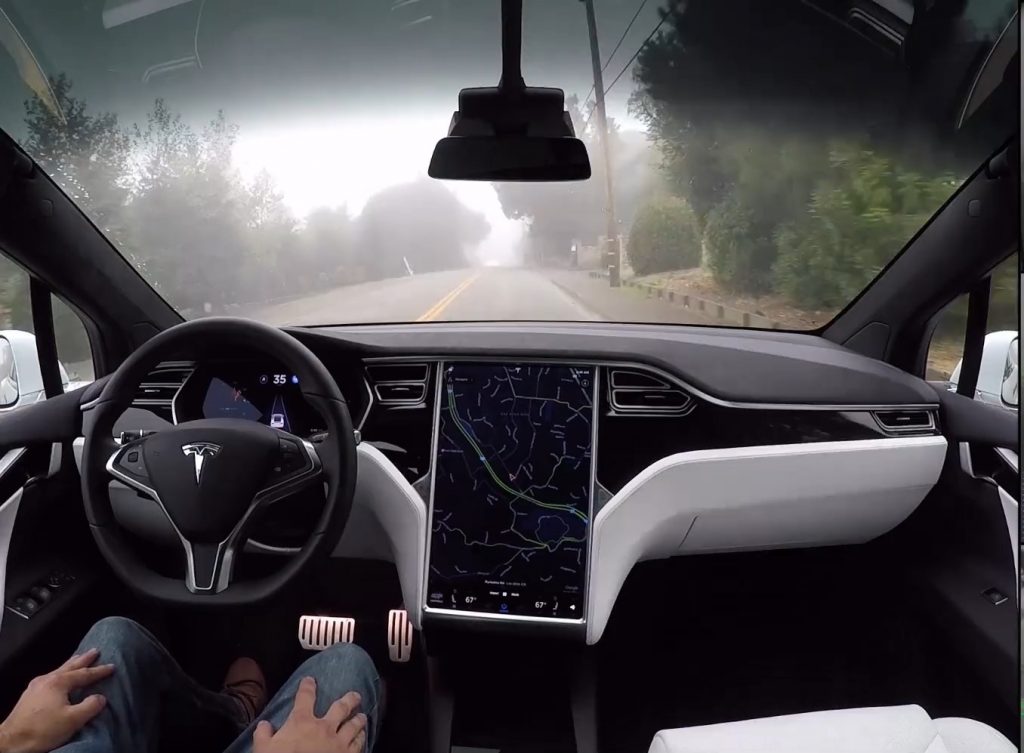

Examples – Tesla’s Autopilot vehicle is the future version of a car equipped with Artificial intelligence. The car promises to have auto pilot driver assist, 40X processing power, Autosteer, 360 deg and high range visibility, auto parking, intelligent lighting etc [28].

Figure 12 – Visualize Plausible Future – Example AI-based Auto-Pilot Technology [28]

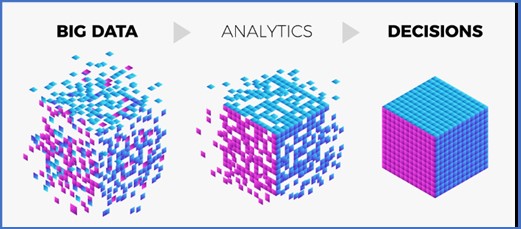

Building a competitive advantage for the future is all about how much data we have and how fast can we process the data to provide meaningful insights and make mission specific decisions [29].

Figure 13 – Visualize Plausible Future – Example Big Data Analytics [28]

A Deloitte study highlights the emerging trend of using big data in automotive industry that will alter the way organizations develop, sell and service their products [30]. Customer Behavior Analytics, Marketing mix analytics, Supply Chain Optimization analytics and Predictive Quality analytics are emerging as powerful data analytics tools.

The other examples include adaptive vehicle to any given context including terrain and energy availability. For example, Vehicle which can adapt to energy resource available like gasoline, diesel, gas, hydrogen, electricity etc. All terrain future vehicle suitable for flat terrain, off highway terrain, water terrain etc. Intelligent vehicles with human assist feature, augmented reality feature to provide richer driving experience and higher safety. Technology merges the real world and virtual world to make wider information visible to driver which otherwise is not available for higher safety, course correction and comfortable driving [31].

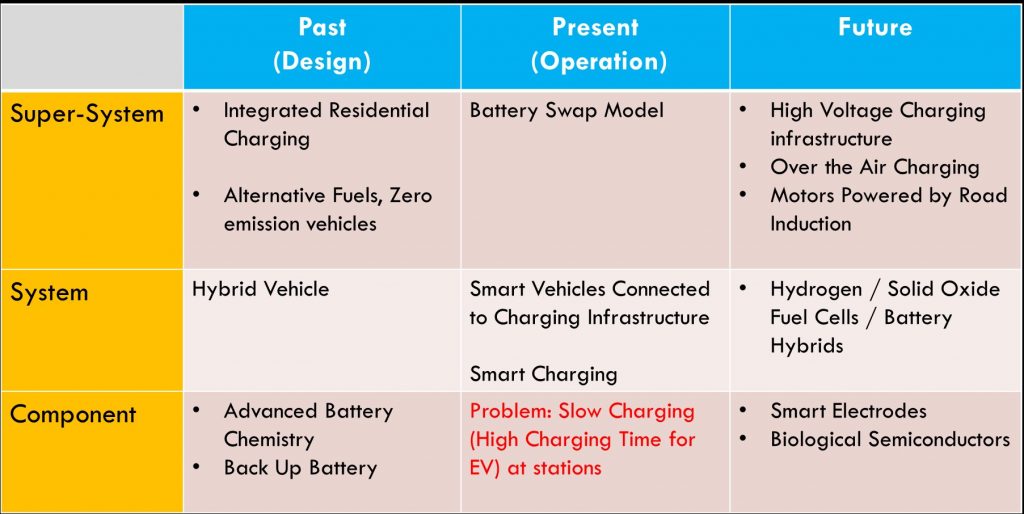

TRIZ 9 Box tool can be very used engaged here to understand the solution possibilities at component, system and supersystem level in space as well as time. The table below shows the spectrum of solutions created for the current problem of slow charging of electric vehicle.

Figure 14 – TRIZ 9 Box Tool Example

Conclusion

Developing a creative mindset is an important skill that mobility engineers need to build. There are six important elements of a creative mindset

- Gather Insights

- Embrace Constraints

- Discover & Engage Resources

- Explore Wider & Deeper

- Think Systemic

- Visualize Plausible Future

Though we have described these six tenets through examples from the automotive industry, these fundamental principles are relevant to all industries.

References

- Mobility Engineer 2030 – a dedicated column for engineering students whoa spire to become mobility engineers, pp. 40 – 42, SAEINDIA, Mobility Engineering, September 2020.

- https://www.fisita.com/documents/FISITA_White_Paper_Mobility_Engineer_2030.pdf

- https://www.weforum.org/agenda/2015/01/whats-the-difference-between-creativity-and-innovation/

- Creativity in Engineering, David Cropley, Multidisciplinary Contributions to the Science of Creative Thinking, Chapter 10 (pp. 155-173), London, UK: Springer.

- Halizah Awang, 2008, Creative Thinking Skill Approach Through Problem-Based Learning , International Journal of Educational and Pedagogical Sciences.Vol:2, No:4

- Kazem Kazerounian,2007, Barriers to Creativity in Engineering Education: A Study of Instructors and Students Perceptions, Journal of Mechanical Design · July 2007

- https://www.caranddriver.com/research/a31995350/self-parking-cars-quick-guide/

- Dadhich, 2016, Key challenges in automation of earth-moving machines ,Vol 68, Journal of Automation in Construction.

- https://www.bosch-mobility-solutions.com/en/solutions/driving-safety/electronic-stability-program/

- https://www.donaldson.com/content/dam/donaldson/aerospace-defense/literature/north-america/f112270/Pulse-Jet-Air-Cleaner.pdf

- Small Wonder, the authorized story of the making of the Nano, Philip Chacko, Christabelle Noronha and Sujata Agrawal.

- https://www.dezeen.com/2015/10/15/microlattice-metal-worlds-lightest-material-boeing-movie/

- Opposed Piston Engine – https://www.techexplorist.com/innovative-opoc-engine-opposed-piston-engine/4280/

- Sukrut Thipse, 2015, Development of Dual Fuel (Diesel-CNG) Engine for SUV Application in India, 2015-26-0058, SAE International

- Mars Orbiter Mission – https://www.isro.gov.in/pslv-c25-mars-orbiter-mission/mars-orbiter-mission-profile

- https://www.slideshare.net/gopu44/simplified-triz-notes

- https://www.motorindiaonline.in/component/jacob-vehicle-systems-advantage-engine-brakes/

- https://www.nhtsa.gov/technology-innovation/vehicle-vehicle-communication

- Digital Twins – https://www.altoros.com/blog/digital-twins-for-aerospace-better-fleet-reliability-and-performance/

- Regenerative Braking – https://circuitdigest.com/article/how-regenerative-braking-works-in-electric-vehicles

- https://patents.google.com/patent/US8360533B2/pt-PT

- EV Battery Swapping – https://www.forbesindia.com/blog/technology/battery-swapping-the-future-of-electric-vehicle-charging/

- EV Charging Stations – https://www.motorbiscuit.com/can-non-tesla-electric-vehicles-charge-tesla-charging-stations/

- https://www.mdpi.com/2313-4321/6/2/31/htm

- https://www.sciencedirect.com/science/article/abs/pii/S0360835220301534

- https://link.springer.com/chapter/10.1007/978-1-4020-7829-3_1

- ZHIQIANG (ERIC) LIU, 2004, Teaching Creativity in Engineering, Int. J. Engng Ed. Vol. 20, No. 5,

- https://www.tesla.com/autopilot

- https://towardsdatascience.com/how-is-the-current-state-of-big-data-analytics-in-controlling-1273c725ac6a

- https://www2.deloitte.com/content/dam/Deloitte/uk/Documents/manufacturing/deloitte-uk-automotive-analytics.pdf

- https://www.relaycars.com/blog/augmented-reality-automotive-safety-drive-future

Authors:

|

Dr Shankar Venugopal is a Vice President at Mahindra & Mahindra. He leads technology innovation, intellectual property and knowledge management. He is also the Dean of the Mahindra Technical Academy. He holds a doctoral degree in materials science from the Indian Institute of Science. He has 20+ years of industry experience across GE, Dow, Honeywell, Cummins and Mahindra. He holds ten US granted patents and ten Indian patent applications. |

|

Mr. Tushar Kanikdale,is presently working as Technical Project Leader at Cummins Technical Center India. He is TRIZ-Level3 (Theory of Inventive Problem Solving) experts and specializes in advanced systematic innovation and problems solving tools. He is also certified black belt and Master black belt. With 17+ years of industry experience he has also trained 500+ engineers on TRIZ, Systematic Innovation and Six Sigma. He is committed to the mission of empowering technical community with advanced research and innovation skills, mindset and toolkit for developing next generation products. |