Design Thinking for Mobility Engineers

Introduction

We had introduced Design Thinking (DT) as a powerful method for Mobility Engineers to pursue innovation driven by customer insights [1]. It is important for the automotive design engineer to understand and appreciate his customers and users well –their constraints and pain points. He has to use these customer insights to precisely define the right problem to solve. The DT methodology provides a framework and suite of tools and techniques that help the engineer to observe his users and unambiguously understand what they like and what they don’t like. DT enables automotive engineers to design and build products that deliver great value to the end-user. DT greatly enhances the innovation and customer focus of the Mobility Engineer.

In the first part on the Design Thinking series, we discussed the first two stages of the methodology. We understood the importance of Empathy in understanding the job the user wants to get done and the challenges they face to get that done. We learnt how to conduct Empathy exercises to get key insights about the users. We also discussed about the second stage of Design Thinking – Define. In the Define stage we learnt how to analyse the user’s challenge and convert the Human challenge into a Technical one. We concluded the article by defining the ‘How Might We’ statement – an actionable technical challenge.

In this article, we are going to discuss the third stage of Design Thinking – Ideate. The Ideate stage is the heart of the Design Thinking process. We describe ideation as a combination of two competing cognitive processes – Divergent thinking and Convergent thinking. We provide tools and techniques that will enable mobility engineers to excel in the Ideate stage of the DT process.

Application of Design Thinking

Before we dive into the Ideate stage, let us discuss a couple of very commonly seen applications of Design Thinking in Automotive and other industries.

A ‘Shattering’ Innovation

In an unfortunate event, if a modern-day car gets hit on its windshield, the glass does not shatter into pieces. This is a very common phenomenon now but was not the case before the mid-1940s. An innovative company with the name The Tucker, was pioneer to various engineering and safety innovations. Engineers at The Tucker observed that there are multiple fatalities caused by broken pieces of glass from the windshield in the event of a car crash. Sometimes even under low impact conditions, the windshield glass would cause more harm than the crash itself. The engineers could have looked for solutions of the unbreakable windshield. But because they were Design Thinkers, they realised the importance of coming up with a simple cost-effective solution that solves the customer’s concerns on windshield breaking rather than designing a complex technology or expensive solution. They ensured that the solution is desirable to the customer (no discomfort or threat to personal safety), technically feasible (based on a readily available technology) and economically viable (cost-effective). The Tucker team leveraged the serendipitous invention of Safety Glass by Edouard Benedictus and applied it on Tucker Torpedo’s windshield [2].

What’s Beautiful, sells!

AirBnB is an amazing innovation in the hospitality industry. But the early days of the company had not been the best. They believed that they tapped the right need of travellers by providing low-cost accommodation while allowing the hosts to earn from their idle asset. But it came as a shock that most of the available premises were going unrented. Being Design Thinkers themselves, team AirBnB closely observed their customer behaviour and realised that the hosts often upload shaky, blurry images of their premises which does not leave a very good impression on a potential customer. They could empathize with the customer who is unable to decide because of the poor-quality images of the property. They could also empathize with the property owners – they realised that the owners were posting poor images because they lack training. The AirBnB team then started visiting the hosts, training them on taking good high-quality pictures and uploading those on the website. This simple idea, based on customer insight, doubled the number of bookings on AirBnB within a short time [3]. Once we observe the root cause of a problem, we can turn around the situation with a simple idea.

Ideate – Stage 3 of Design Thinking

The third stage of Design Thinking is one of the easiest. This is because human beings are naturally creative and are good at coming up with ideas [4]. But the success of this stage depends a lot on how well we have done the previous two stages of Design Thinking. Without having a very sharp technical challenge statement, the efforts to create ideas to solve becomes futile. Let us assume that a mobility engineer follows all the processes explained in the first two stages and generates a very crisp technical challenge to solve. Now let us understand how to create the best solution that solves the user’s problem. A structured ideation process follows two distinct stages:

(i) Divergent Thinking and (ii) Convergent Thinking.

The Divergent Thinking process, is often referred to as open ideation where the participants focus on the quantity of ideas rather than the quality. There should be no judgement during this phase of ideation. All ideas are encouraged during this phase. Some common divergent thinking ideation techniques include brainswarming [5], brainstorming [6], trigger-based ideation like SCAMPER etc. Silent initial phase of idea generation helps during brainstorming as it is often found that the introverts tend to refrain from voicing their ideas. Once the silent idea generation process is done, participants should build upon each other’s ideas without any criticism. All ideas should be noted down before the process enters the next phase – the Convergent thinking phase.

Let us take a brief look at the origin of collective idea creation techniques. The word brainstorming was originally introduced by Alex F. Osborn in 1953 through his book “Applied Imagination: Principles and Procedures of Creative Thinking”. Alex Osborn was greatly influenced by the Creative thinking theories of Graham Wallace, which included the fundamental elements of a creative thinking process, incubation, intimation, illumination, and verification, aspects of which can be seen Osborn’s design of the brainstorming process.

Osborn was very specific about what his proposed process of brainstorming entailed. He came up with four basic rules for the process. The first rule established the end goal of the process, which was to generate as many ideas as possible. The emphasis was on the quantity of ideas generated rather than the quality. The second rule was that no one was to criticize an idea. Osborn wanted to keep all judgments out of the idea generation process, so judgments were to be deferred until the brainstorming process was over. The third rule was that wild ideas were welcome, in fact, they were encouraged. The fourth rule was that participants were permitted to combine ideas or improve on each other’s ideas [7].

There have been some views that challenge the second rule that strongly discourages criticism. A recent study has raised the question should we allow criticism while brainstorming [8].

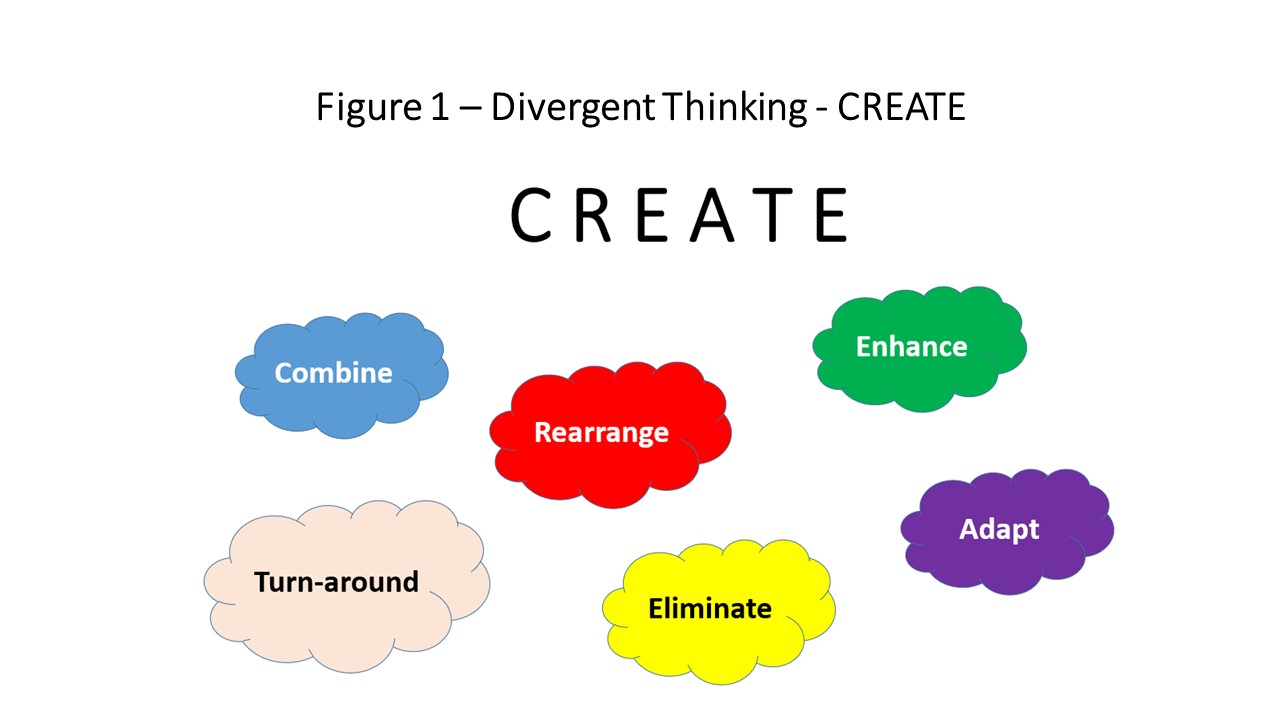

We introduce a powerful divergent thinking tool – CREATE – that would help mobility engineers to create many ideas. CREATE is an acronym for Combine, Rearrange, Enhance, Adapt, Turnaround and Eliminate. The engineer can take an existing product and use these six triggers to drive ideation along six directions.

But where does one start in order to come up with an innovation?

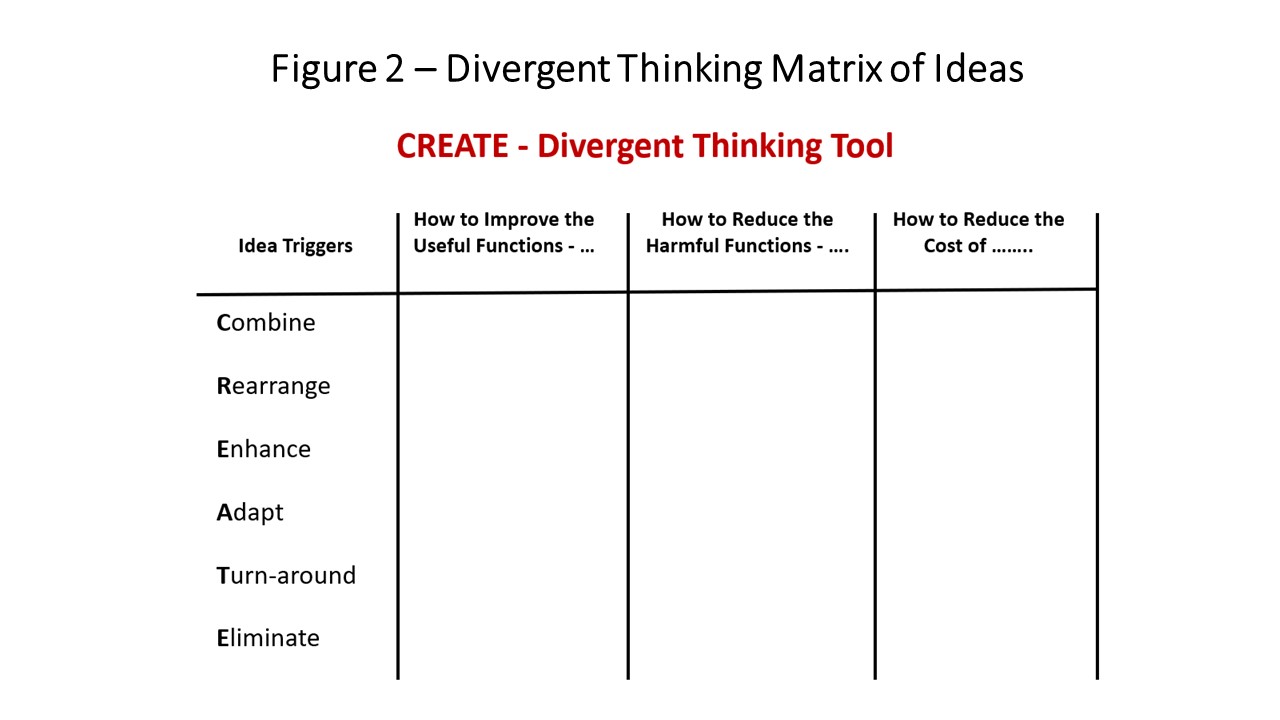

According to TRIZ (theory of inventive problem solving), one can improve any product by working in three directions – (i) how to improve the useful features of the product, (ii) how to reduce or eliminate the harmful features of the product, and (iii) how to reduce the cost of the product. When the useful features of the product reach infinity, the harmful features are reduced to zero and the overall cost of the product comes down to zero as well, the product is said to have gained Ideality according to TRIZ [9]. As a Design Thinking engineer, one has to aim to design the final solution as close as possible to the Ideal solution.

Combining the concept of Ideality from TRIZ and the CREATE tool now the engineer can generate ideas to address these three directions in six possible ways.

Figure 1. CREATE – a Divergent Thinking Tool

Figure 1. CREATE – a Divergent Thinking Tool

The mobility engineer can consider combining smart and connected features in the current ICE (internal combustion engine) vehicle to create value for the customer. The design engineer can rearrange the seats in a shared mobility vehicle to offer more privacy to the users. The engineer can enhance the battery storage capacity of the EV to reduce the range anxiety of the user. The engineer can adapt lightweighting ideas from the space industry to reduce the weight of EV and thereby improve its range. The engineer can turn-around the situation of the battery losing its energy by providing an inductive-coupling and dynamic charging feature so that the EV will accumulate more charge when it is driven more distance. The engineer can even dare to eliminate the driver by providing advanced (Level 5) autonomous driving features in the vehicle. The mobility engineer has to budget one hour for divergent thinking and invest at least ten minutes with each of the six triggers.

Figure 2. Divergent Thinking Matrix of Ideas

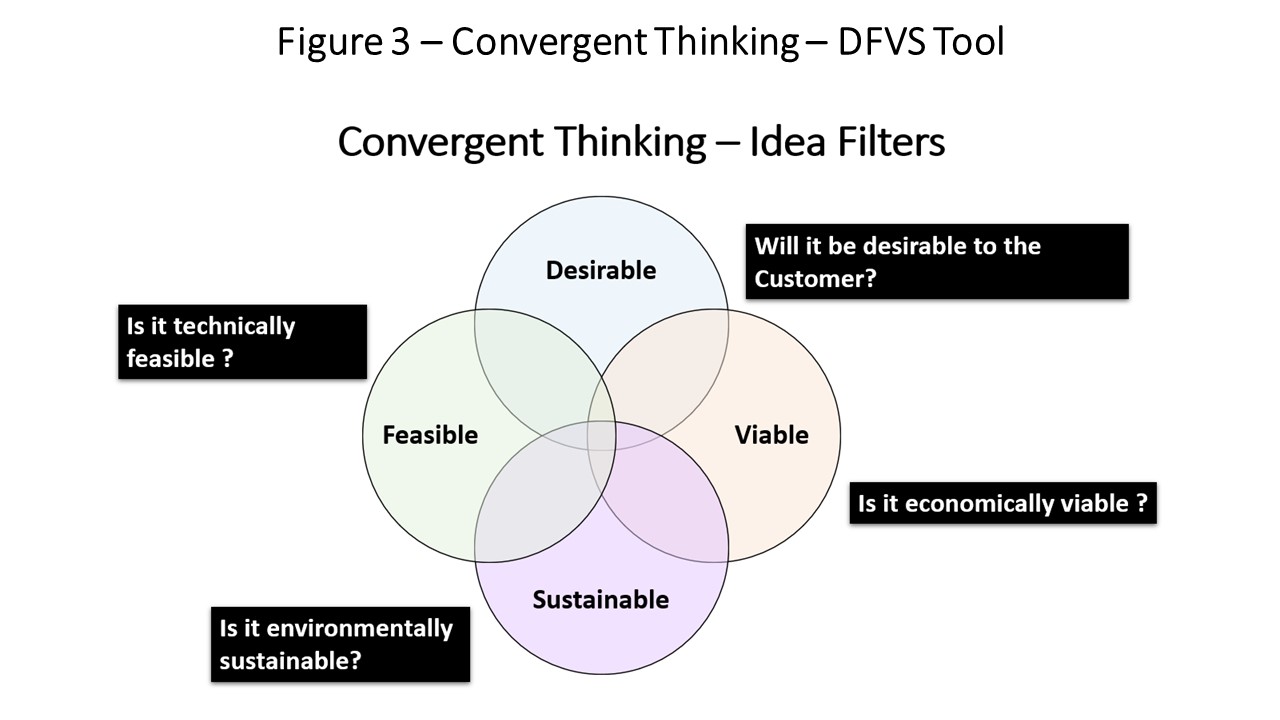

In the Convergent thinking process, the participants should focus more on the quality of the ideas [10]. The aim of this phase is to select the best idea to be implemented in the current context. To select the best idea, participants should rate each of the ideas generated in the divergent thinking phase, on certain parameters [11]

- i) User Desirability

- ii) Technical Feasibility

- iii) Economic Viability

- iv) Environmental Sustainability

Figure 3. Convergent Thinking Tool (DFVS)

User Desirability – the most important of all the parameters is to rate the idea from the perspective of the end user. An idea can be technically brilliant, but the final offering will need the user’s acceptance to make it successful. If the end -user is not happy about using the product, then a high rating on the other three parameters will still not help. To rate ideas on user desirability, mobility engineers should ask two questions –

- A) How well does the idea solve the main problem that the user complained about?

- B) How much will the user love to see this idea implemented?

It may be wrong to assume that a positive answer to question A will imply a positive answer to question B. For example, an automotive design engineer may think that a flexible door handle is a good solution to the ‘door handle hitting the knee issue’ problem. But the flexibility creates an occasional vibration which may be irritating to the customer. Though the solution solves the problem that the user complained about, it is not one that the user loves to see implemented.

Technical Feasibility – this parameter rates how easy it is to implement the proposed solution. Even if an idea is highly rated by the user on desirability, there still remains the question whether it is possible to make the solution work. To rate ideas on Technical Feasibility, mobility engineers should ask questions such as –

- A) Is the technology maturity (TRL, Technology Readiness Level) sufficient to be deployed in a product?

- B) How easy it is to reliably procure the components and sub-systems required to bring this idea to life?

- C) Does the team have the necessary competency (knowledge and skill) to develop the tech building blocks of the solution and successfully integrate into a robust product?

- D) Is the ecosystem ready to support the performance of the product?

When an automotive engineer looks at Hydrogen powered vehicles, she has to assess the TRL and ensure that all technical risks have been mitigated. The current chip shortage that the automobile industry is facing is an example of potential low score on technical feasibility, arising from supply chain challenges. When a team with rich experience in ICE technology starts working on an EV product, they have to assess their technical competency in EV tech and plan to reskill themselves very quickly.

A mobility engineer while designing an EV product, especially while designing the range of the vehicle and the time for charging, should consider the availability of fast charging stations. The engineer should also consider the availability of battery materials and access to recycling facility, while deciding the specific energy storage system for the EV. Without the support of the ecosystem, the performance of the EV will be sub-optimal.

Economic Viability – this parameter rates how good the financial returns will be when the solution is implemented. Often an idea is highly user desirable and is very much manufacturable, but the overall cost to develop is way more than what the user can pay for – such cases make the solution low on economic viability. A solution is deemed non-viable if the seller is not able to make sustainable business by offering the solution. To rate ideas on economic viability, mobility engineers should ask two questions –

- A) how much does the next-best solution cost (the solution that the user is currently managing his situation with) – how much more will the newly proposed solution cost – will the user see sufficient value addition and be ready to pay the incremental amount?

- B) how easy is it to get paid for the solution – is the total addressable market (TAM) large enough to steadily grow the revenue generated by this product? How do we build a stable and growing business based on this product / solution?

Environmental Sustainability – This parameter rates the solution on the impact it has on the environment. To rate ideas on environmental sustainability, mobility engineers should ask:

- A) Will the product harm the environment directly or indirectly while it is being manufactured, used, repaired or discarded (across its entire lifecycle)?

- B) Will the constituents of the product, after it is disposed at the end of its life (EOL), cause any environmental challenge?

Environment is not only about global warming or plastic waste. Environment, in this case, is more than just the planet – it includes even the living beings that are somehow impacted by the solution. For example, if developing an effective solution requires some chemical reaction that may release a poisonous gas in the locality, the solution should be rated low on this parameter. You might have read about the environmental challenge posed by wind turbine blades – though the wind turbines generate renewable energy that is good for the environment, they pose an environmental challenge at the EOL (typically ten years). The huge wind turbine blades are made of composite materials that are difficult to break or decompose – they would need very large land space for their disposal.

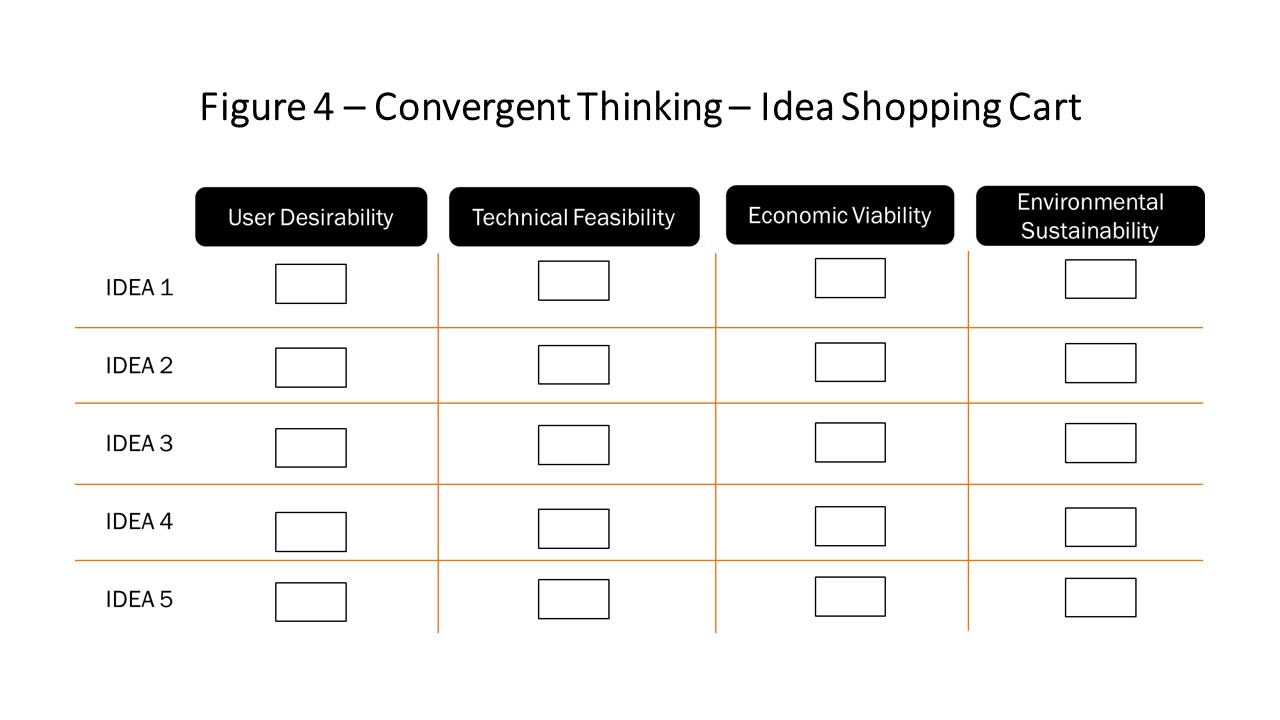

Mobility engineers should rate all their ideas by assigning relative scores on these four parameters and build a decision matrix. This may be called the Idea Shopping Cart. Just as in a super mart, a decision maker picks up one product over others of the same type based on certain parameters in mind and puts it in the shopping cart. The best idea is picked up using this method. This gets it the name Idea Shopping Cart method. Below is a sample Idea Shopping Cart template. The scores can be High (5), Medium (3) and Low (1).

Figure 4. Convergent Thinking – DFVS Idea Prioritization Tool

One mistake that most engineers tend to make here is that they sum up all the scores and consider the idea with the highest score as the one to be chosen. However, this template is a decision matrix. One should use it in a way to identify the most valuable parameters for the context and accordingly choose the best idea. For example, one idea may have high user desirability, economic viability and environmental sustainability score, but score low on technical feasibility, while another idea may have high technical feasibility, economic viability and environmental sustainability and moderate user desirability score.

Decision makers may decide to go with the first Idea even if it is low on technical feasibility just because the user desirability is high and they consider it important to their context. The implication of such a decision is that the team may have to work on learning the technical knowledge required to implement the solution. They may have to collaborate with others who possess that technical competency.

The outcome of this stage is one single solution that the team considers the best among all the other available ideas. Each stage of Design Thinking being a lengthy process, an engineer should check at this point that the chosen solution is solving the ‘How Might We’ statement that was formulated at the end of the Define stage.

Conclusion

The Ideate stage of Design thinking is as important as the previous two stages (Empathize and Define). It requires an engineer to be open to new perspectives. Out-of-the-Box ideas get generated when an engineer gives the industry specific challenge a generic definition and starts looking into other industries and sometimes other domains for similar solutions [12][13][14]. This concept of generalizing a specific problem, then looking for generalized solutions from various other industries and domains, learning from existing solutions and then devising a solution suitable to the specific problem is a very systematic approach to problem solving. This systematic approach in TRIZ is referred to as Function Oriented Search (FoS) [15]. The Ideate stage is deemed successful if the engineer is able to create many ideas and identify the best of all the available solutions after rating each on the four critical parameters. In the next two stages, i.e., Prototype and Validate, the chosen idea is tested against all possible assumptions and evaluated by user groups. We will discuss in detail the last two stages in the next and final article of this series.

References

- Design Thinking for Mobility Engineers – Part 1 – Empathize and Define, Sayantan Mukherjee and Shankar Venugopal, Mobility Engineering, pp 41, Vol.9, Issue 1, January – March 2022.

- Tucker History; Dezo’s Garage – Vintage Car

- 11 Products & Services Made Using Design Thinking; IDEOU Blog

- Creative Confidence: Unleashing the Creative Potential Within Us All; Tom Kelly, David Kelley; 2018

- Tony McCaffrey; BrainSwarming: Because Brainstorming Doesn’t Work; Harvard Business Review webinar; June 2014

- Hal Gregersen; Better Brainstorming; Harvard Business Review Magazine; March–April 2018

- The Journey of Brainstorming, Hanisha Besant, Journal of Transformative Innovation, Issue: 1, Volume: 2, 2016.

- Should we allow criticism while brainstorming, Dylan Walsh, Ideas that Matter, MIT Sloan, Feb 2021 (https://mitsloan.mit.edu/ideas-made-to-matter/should-we-allow-criticism-while-brainstorming)

- G Altshuller; And Suddenly the Inventor Appeared. Translated by Lev Shulyak, Technical Information Center

- Convergent vs. Divergent Thinking; Anne Manning; YouTube Channel – Harvard Professional Development; May 2016

- Kristann Orton; Desirability, Feasibility, Viability: The Sweet Spot for Innovation; Medium; March 2017

- Cyril Bouquet, Jean-Louis Barsoux, and Michael Wade; Bring Your Breakthrough Ideas to Life; Harvard Business Review Magazine; November–December 2018

- Giovanni Corazza; Creative thinking – how to get out of the box and generate ideas; TEDx Talks; March 2014

- Loran Nordgren and Brian Lucas; Your Best Ideas Are Often Your Last Ideas; Harvard Business Review; Jan 2021

- Simon Litvin; New TRIZ-Based Tool—Function-Oriented Search (FOS); ResearchGate Publication; January 2004