Systems Thinking for Mobility Engineers

Introduction

The automotive industry is seeing a huge transformation due to the accelerated growth of new technologies like AI, IoT, robotics etc. Fossil fuel-based cars are being replaced by electric vehicles while connectivity and immersive technologies are making vehicles smarter and better [1]. The automotive original equipment manufacturers (OEMs) are busy strategizing to adapt the new technologies at the right time to stay relevant. Automotive OEMS are thinking beyond the product and looking at complete end-to-end mobility solutions. For example, the Project Vector by Jaguar has been dubbed an “electric mobility platform” and not just an electric car; a move towards “Destination Zero”, JLR’s ambition to achieve a future of zero emissions, zero accidents and zero congestion [2][3].

New vehicles feature automation and connectivity that make the vehicle intelligent. While the enabling technologies like AI and IoT are in the background, the design of the vehicle is getting increasing focus. Factors like styling, safety, comfort are on the priority list of the design engineers. Automotive engineers, aspiring to enter the industry by 2025, are preparing themselves for this change by picking up skills in emerging technologies, learning vehicle design and advances in automotive engineering that will help them to excel in the mobility industry. Many automotive technology innovators have hinted that success in designing future mobility products will demand something beyond traditional engineering skills. In a competitive landscape, OEMs are looking to use innovation to create differentiators and gain competitive advantage. Automotive design should transcend from just creating a vehicle as an engineering marvel, to implementing a full spectrum of innovations with a human-centred approach. Design engineers need to understand how their product interacts with the customer at various stages like sale, service, use, upgrade, disposal etc. The emerging automotive industry needs engineers to become design thinkers to drive impactful innovation and product differentiation. In this article, we will discuss how Automobile engineers can create amazing customer experience by learning and applying Design Thinking across the entire lifecycle of the automotive.

Design Thinking enables innovative mobility solutions

Design is the lifeblood of the mobility business. In 1908 with the launch of the model T, ford made automobile affordable to the common man. The vehicle was neatly designed to perform its core function of transporting people and goods. Over the years, Ford concentrated on improving the technical features of the vehicle making each version better than the previous one. Till 1920, the model T remained the top selling automobile – a four-wheeler machine that was designed to be technically the most efficient one. General Motors took a different approach to differentiate their vehicle offerings. The then President and CEO of General Motors (GM), Alfred P. Sloan identified that car owners like to exhibit their vehicle as status symbol. GM then rolled out five brands under the mother company and positioned those for different price segments [4]. This is an early instance when the human factor was taken into consideration while designing an automobile. Though the influence of other machines in the mobility space like aircrafts and ships were still very much predominant, automotive engineers increasingly realised that caring for the needs of their end consumer is important to design better cars. Voice of Customer (VoC) became a standard procedure to capture customer needs and design engineers would refer to these needs while making design recommendations.

With many new electric vehicles entering the market, the OEMs are looking at ways of creating differentiated product offerings. The power of the engine, smoothness of the drivetrain, incremental improvements in fuel efficiency etc. are no longer the only factors to focus. The conventional drivetrain which used to have close to 2000+ moving parts is being replaced by an electric one which has less than 20 components. Most of the automotive OEMs procure their battery pack, which is the heart of the electric vehicle, from the leading battery OEMs. The same is true with the electric motors and automotive electronics components. The looks and performance of the new EV offerings will look very similar unless the OEMs find new ways of delivering value to their customers.

Consider an example of driving long distance in an EV with a limited range. If I am driving from Chennai to Bangalore (~ 350 km) in an EV whose range is only 200 km per charge, then I will be anxious about my battery running out of charge. If I am used to reaching Bangalore in 5 hours in my ICE vehicle and if I am ready to compromise for an extra 2 hours’ drive, then we have 350 Km to be covered in 7 hours. The 7 hours will include the time spent to charge the EV battery a few times (2-3). The connected features in the EV helps the user to know the location of the EV chargers on his route, their availability (updated real-time), residual charge on the battery etc. Thus, the user can plan his trip with a couple of breaks at the charging stations and still reach his destination in time. Here the engineer should not limit his innovation only to the product (EV) but extend it to the ecosystem comprising of EV chargers. The engineer has to understand the range anxiety that frustrates his customer and has to deploy creative solutions to keep his customer engaged and happy. These innovations are not limited to the vehicle but spread across the entire ecosystem involving the EV chargers. Hence, we use the term “Mobility Engineer” rather than “Automotive Engineer”.

Automotive engineers need to find unique insights about the way the customers use their vehicles and convert those into insights into unique value proposition for their customers. To effectively uncover the unarticulated or latent needs of the customers and derive valuable insights, an engineer requires two critical skills – (a) ability to understand the constraints and pain points of customers and (b) the eagerness to help customers to overcome their problems. When one just feels sorry for others and is not keen to solve the problem, the feeling is described as pity [5]. For example, an engineer may have heard a complaint from the customer that the Glovebox lid hits the knee often when opened. She feels pity for the customer and might say “that is really unfortunate”. But if she feels a little stronger for the customer and tries to redesign the glovebox, this feeling for the customer is described as sympathy. Gradually, as she feels more about the customer and cares more to act, she may go ahead and experience in the car what the customer experiences while opening the glove box lid to understand why the problem is happening. The engineer’s empathy towards the customer helps her to understand the precise problem and create improved designs. Finally, if she decides to not let go the problem but to act upon it by solving the problem of glovebox lid once for all, she may apply her engineering knowledge to better design the opening of the glove box that does not hit the knee. She successfully pitches her idea, test her prototype, consults with manufacturing team to make her design manufacturable and also convinces the business to introduce the new design in the product. This is when the engineer expresses compassion for the end user.

Engineers need to learn how to empathise with their customers, deeply analyse the challenges they face, explore many ideas and iteratively improve the ideas to solve those challenges. This is when they move from being sympathetic to being empathetic and compassionate. The application of the Design Thinking principles helps an engineer to practise empathy in product design. The future of mobility will be shaped by automotive engineers who are design thinkers.

Introduction to Design Thinking

Design thinking paves the way for an automotive engineer to logical or analytical thinking with creativity that is needed to generate incredibly desirable solutions.

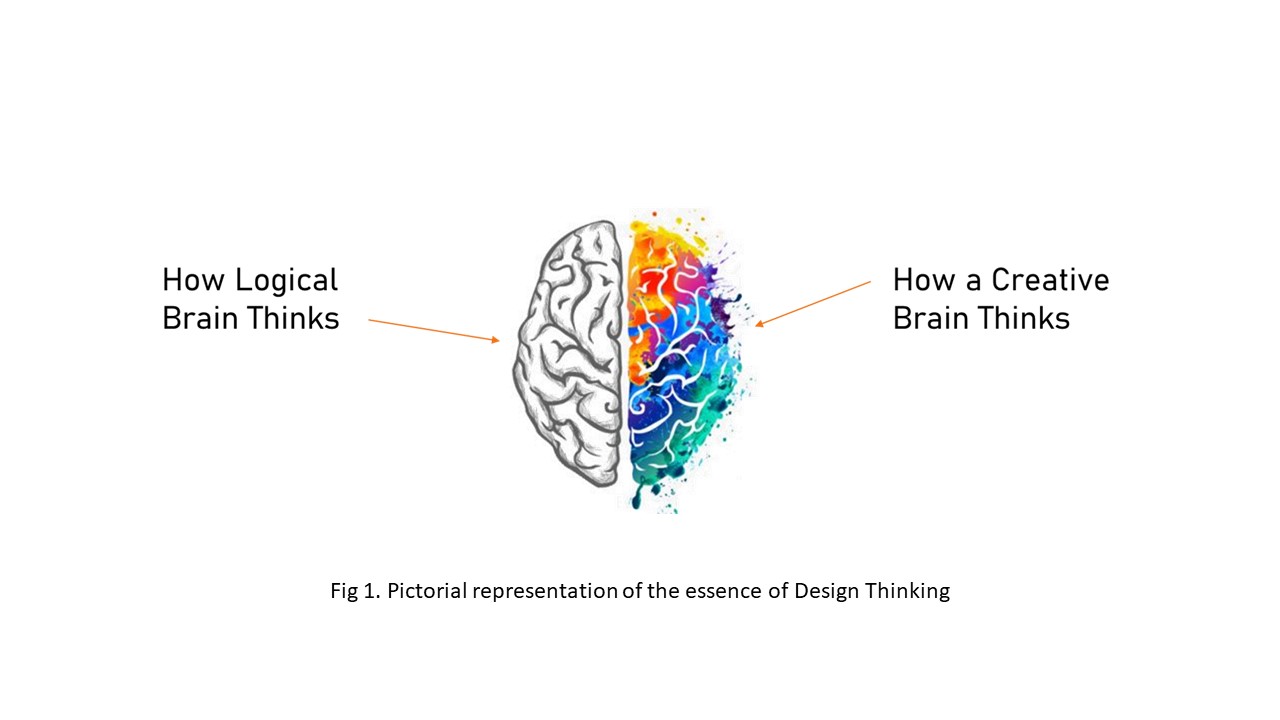

Most engineers are trained to think logical / analytical – the amalgamation with creativity is where design thinking helps an engineer to innovate. The automotive engineer can practice design thinking by following the five stages as shown in Figure 2.

Developing a successful solution, by using design thinking, requires multiple iterations. A “Design Thinking Mobility Engineer” must understand the iterative nature of the process and be patient while developing an innovative solution. We will look at each of these five stages of Design Thinking in detail. We will illustrate each stage with appropriate examples that will help engineers to understand the nuances involved in each stage of the process and develop successful products [6].

First Stage – Empathize

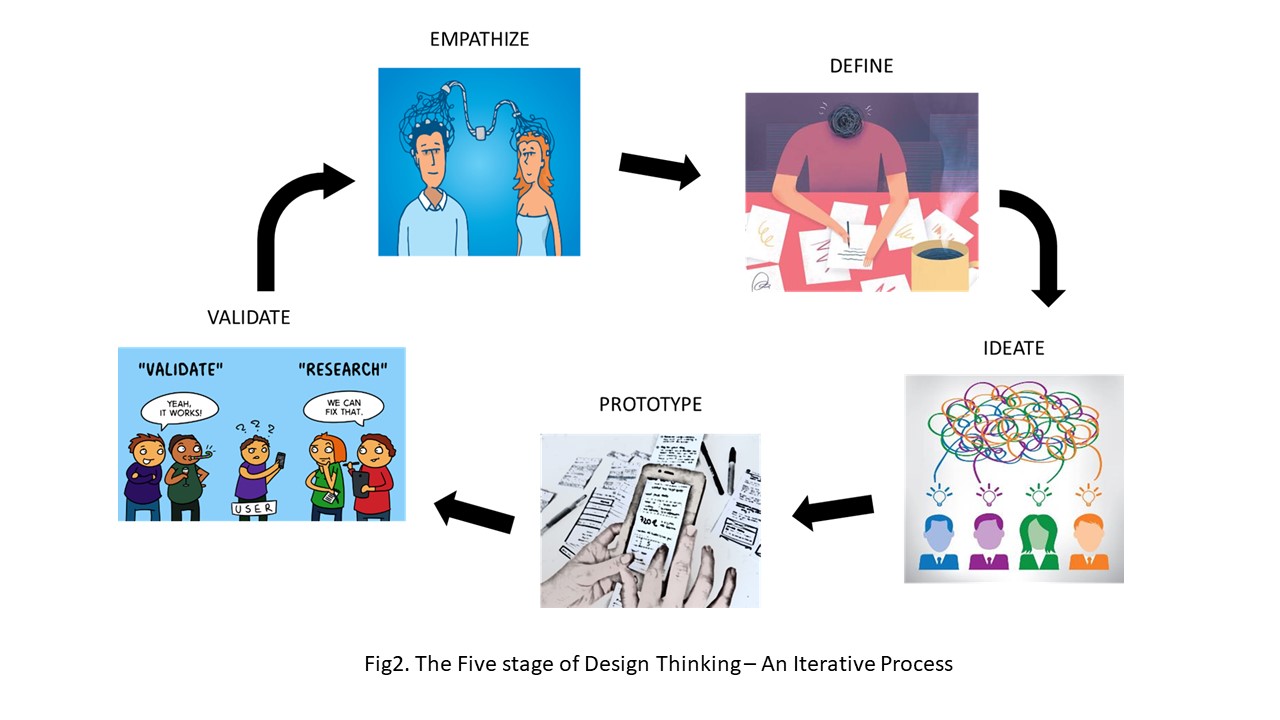

The first stage of Design Thinking is called Empathize. As the name suggests, this stage requires an innovator to be empathetic towards the target user group for whom the product is being designed Empathy is the capacity to place oneself in another’s position. Being empathetic and generating insights requires an innovator to do the following four things:

- a) Creating persona of the target user

- b) Overcoming cognitive bias

- c) Engaging with the user

- d) Experiencing what the user experiences

(a) Creating persona of the target user

Before starting an innovation project, an engineer should decide for which target user group the product is getting designed. There are multiple user groups with unique needs. A car may be driven by a chauffeur or a young working lady or a middle-aged family man or anyone else. If an engineer is designing the vehicle for the one in the driving seat, it is important to decide who she is having in mind while designing the car. Similarly, the car may be designed for someone sitting in the co-passenger seat or the rear rows – it may be a restless toddler or an elderly person. Having a persona in mind for whom the design is made, helps engineers to focus their design efforts on the needs of their stakeholder. The tendency of designing for all should be avoided as much as possible to reduce risk of design chaos (a situation where no one stakeholder’s needs are fully satisfied through design). One single persona also helps in bringing clarity to the whole project.

To rightly create a user persona, an engineer should know five key things about the target stakeholder:

- i) What job the stakeholder wants to get done by using the product in question [7]?

Example – If an engineer is designing the car’s driver seat, the probable job to be done by using the seat is “a comfortable travel with no body pain even after a long drive”

- ii) How are they managing today?

Example – There is probably some compromise that they are making with the existing seats.

iii) What pain do they have with the existing solution(s)?

Example – The best solution available in market is an aftermarket fitment that is just good to increase the duration before the body pain kicks in

- iv) How do they measure the performance of a solution?

Example – Generally the target user group considers six hours of continuous driving as a benchmark to test a solution

- v) What influences their decision making?

Example – The target stakeholders rely more on recommendations of their friends or people who are long-drive lovers

- Overcoming cognitive bias

Most of us tend to create some sort of image of other people based on the perceptions that we have. These perceptions may not always be true. During the empathy exercise, these perceptions need to be validated to overcome the inherent biases that we might have. These are called cognitive bias. A cognitive bias is a systematic error in our thinking. The impact of cognitive bias on an empathy exercise is very subtle but significant. With a wrong perception in mind, about the target user group, an innovator may avoid asking certain questions which are otherwise important for the context of the project. For example, with an assumption that a farmer interested in upgrading his personal car may not be interested to spend more money for a comfortable driver seat, one may not ask what is the most comfortable seat that user has tried before.

To overcome cognitive bias an engineer may do the following in sequence before getting into an empathy exercise:

- i) Noting down everything that the engineer believes about the user

- ii) Then using secondary research and interacting with people, who most often interact with the target user group, to validate the assumptions

iii) During the empathy exercise, keep looking for evidences that may suggest something different than what has been noted as an assumption about the user group

(c) Engaging with the user

The third and probably the most important part of the empathy exercise is engaging with the target audience. The “Design Thinking Mobility Engineer” should be a good observer and listener to be able to complete this part of the empathy exercise successfully. Engaging with the user group includes doing one-to-one or group interviews. One should keep taking down notes during the interview. It is also important to record what is being said by the interviewees. However, recording the interview has to be done with proper permission taken from the interviewees. An Engineer should opt for as many open-ended questions as possible to let the interviewees open up. It is also important to make them feel comfortable during the interview process. There should not be any sign of intimidation from the interviewer’s side that may make them feel uncomfortable. Noting down the emotions of the interviewed user group and the choice of words used to describe a specific situation, gives the interviewer some key insights. The engineers are encouraged to use the local language to better connect with the users.

For example, while trying to understand what the users feel about the current air conditioning provided in the third-row seat of a SUV, an interviewer got the following reply from User 1, “The cooling is low. It can definitely be better”. The User 2 said, “The third-row seat is suffocating – the air conditioning is just terrible”. Though both the users explained their dissatisfaction with the air conditioning in the third-row seat, the choice of words used were very different and clearly depicts the varied extent of dissatisfaction between the two users. This may be because User 1 uses the third row less frequently than User 2.

Many organisations use data mining and sentiment analysis techniques to gauge social media sentiment of their user group. Data analytics and machine learning are widely used for this purpose. Apart from interviews, observing the way users use the product, gives immense insights. An engineer should take as many digital proofs (picture, video) as possible to capture the way the user uses the product or the emotions they go through while using it. As mentioned earlier, all this has to be done with proper permission taken from the users. Careful observation brings out deep insights that the user may miss talking about when interviewed.

- Experiencing what the user experiences

The last step of the empathy exercise requires an innovator to get into the shoes of the target user. Deep interviews and careful observation can help an engineer feel more sympathetic towards the user group. But it is only when the same experience is experienced, an engineer can become empathetic towards the user. For example, to understand how exactly the air conditioning of the 3rd row seat is, an engineer may actually get into the 3rd row of that SUV and take a considerable long ride.

But it is not always possible to have the same experience as the user in a real-life situation. For example, if an engineer is designing the instrument Panel for a visually impaired passenger in the co-driver seat, she has to understand how it will feel like being visually impaired while trying to operate the controls on the infotainment cluster. In situations like this, an engineer may try to recreate the situation artificially to match the experience of the target user group. In the case of Designing the instrument Panel for the visually impaired passenger, the engineer may try blindfolding herself while using the controls of the instrument panel. The main aim of this stage of Design Thinking is to understand as close as possible the challenges the target user group experiences while using the product to be re-designed which are otherwise not easy to understand.

Second Stage – Define

The second stage of Design Thinking is Define. In this stage we analyse the challenges that the target user group are facing and define actionable technical problem statements to be solved. Engineers often go wrong at this stage because they fail to adequately analyse the user need captured at the Empathize stage. The user has described their problem in a particular way and the engineer, in his eagerness to quickly solve the problem, is tempted to take it as it is without further analysis. Skipping this step is like falling into a trap which we call the Paracetamol trap. Usually, we use Paracetamol when we run a high fever and subside it. But the reduced temperature does not necessarily mean we are getting better. Fever is just a symptom of something going wrong within the body which requires attention and medication. Similarly, most problems that we encounter throw some symptoms that requires further deep diving to identify their root cause. Without solving the root cause if the symptom is just taken care of, it does not eliminate the chance of a recurrence of the problem.

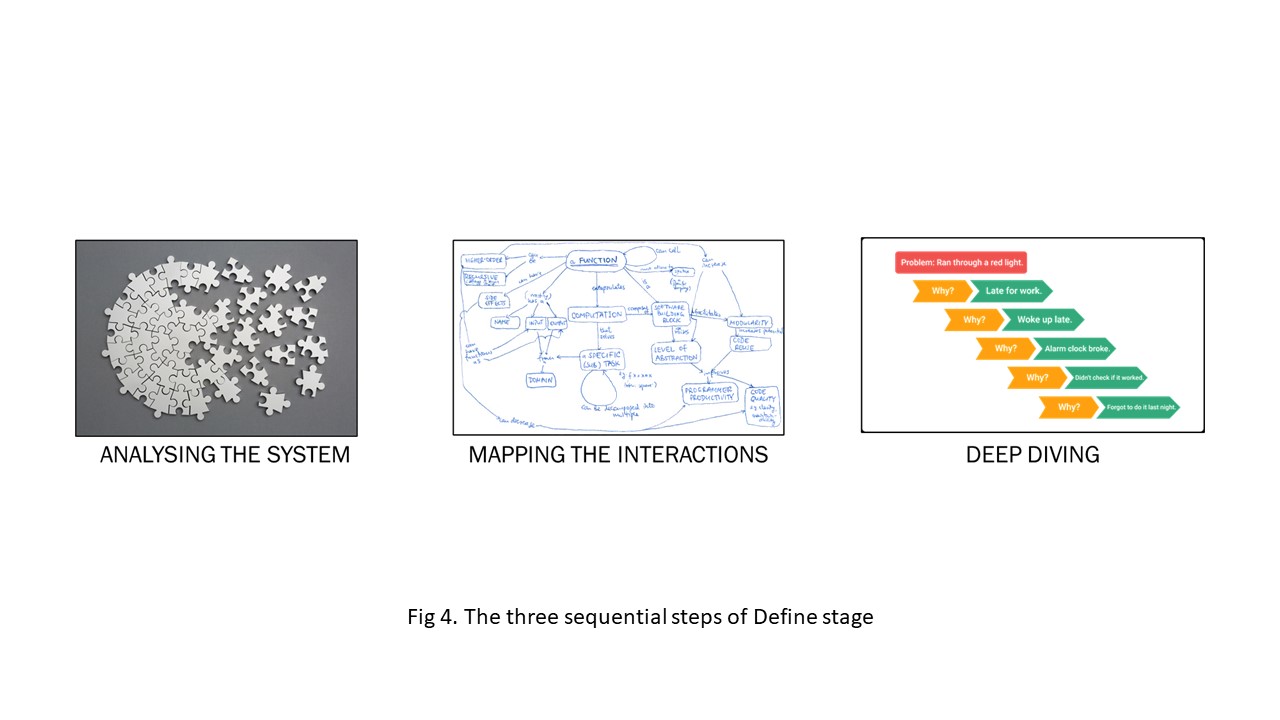

To get to the bottom of a problem an engineer should be doing the following steps in sequence:

- a) Analysing the system which she is trying to redesign or innovate upon

- b) Mapping the interactions of the various components of that system

- c) Deep diving into the specific ‘zone of concern’ flagged by the previous step

(a)Analysing the System

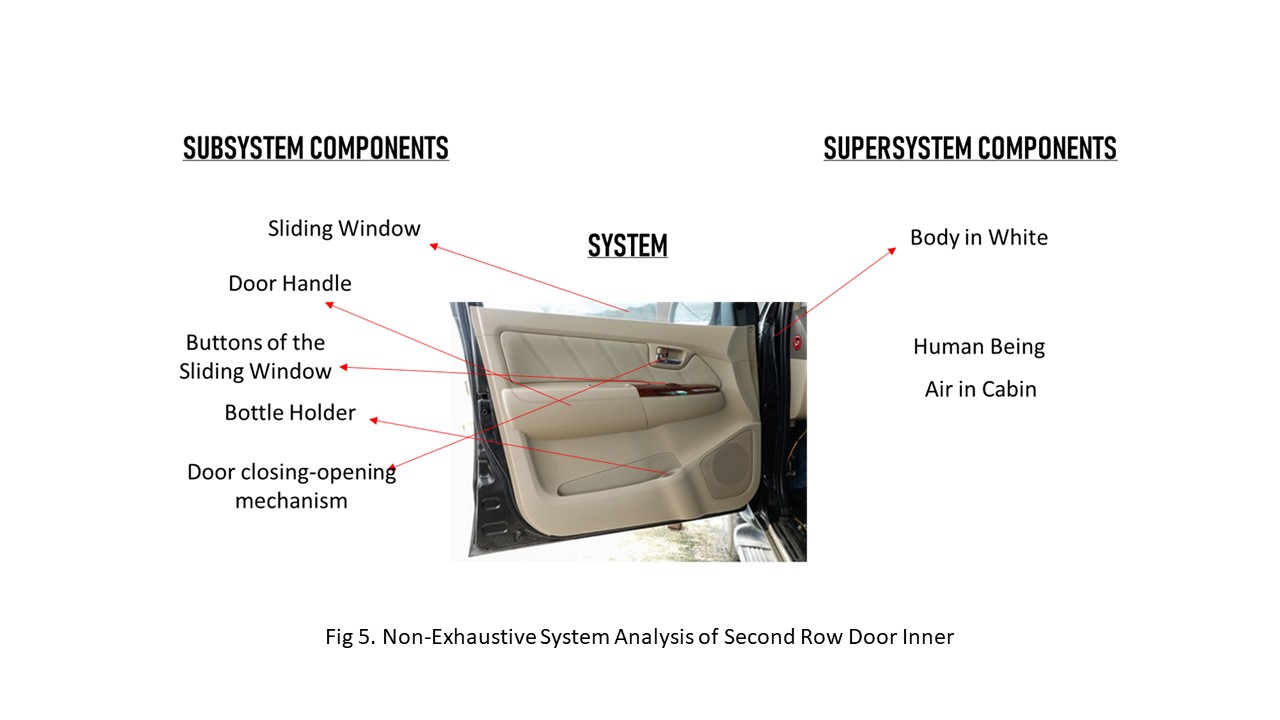

A System is the one that is getting designed by the engineer. Once the system is defined, the process of system analysis requires the engineer to break it down into several components. This is because, while trying to analyse a complex problem it is easier to break it into smaller simpler forms and then try to solve rather than getting overwhelmed by the complexity of the whole. Through systems analysis, an engineer breaks down the system into two major parts:

- i) Subsystems – Components that are part of the system. In other words, components that make the system whole

- ii) Super systems – Components that are external to the system but has a direct connection (physical or virtual) with the system

Let us assume that an engineer has identified a certain challenge that customers face with the current design of the second-row door inner. To complete system analysis, she should define her system, the subsystem and super system components. She defines the second-row door inner as the system and correspondingly identifies the following:

- i) Subsystems – door handle, bottle holder, sliding window, the buttons for the sliding window, door closing-opening mechanism etc.

- ii) Super systems – the passenger, the sliding window motor, the body in white, air inside the cabin etc.

(b) Mapping the Interactions

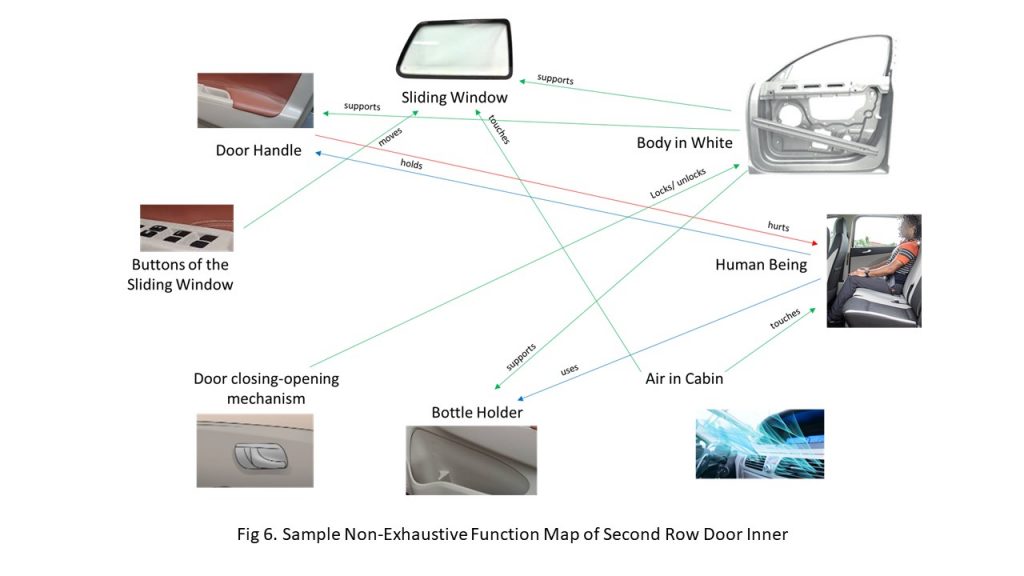

The second step in the define stage is to map the interactions that the subsystem and the super system components have among themselves. This process is referred to as the creation of the function map. The objective of the function map is to identify the ‘zone of concern’ that has to be investigated to finalize the technical challenge statement to solve. To create the Function Map engineers may use a big chart paper (offline) or any online collaboration tool (online). Put down all the super system and sub system components on the chart paper/ online sheet.

Now start with one component and try to figure out the interaction that it has directly with any of the other components. Whenever there is an interaction use an arrow to represent it. There are instances where two components may have more than one type of interaction. Use different arrows to represent different interactions. The direction of the arrow head should be such that it represents which component is making an action and which component is it acting upon. The arrow head should be in the direction of the component on which the action is done. There is a colour coding to be used to represent these arrows.

Green arrow – indicates that the interaction between the two components is necessary and useful

Blue arrow – indicates that the interaction is necessary and useful but has a further scope of improvement

Red arrow – indicates that the interaction is unnecessary or harmful for the component on which the action is done

The arrows should also carry a verb to describe the action that is being done. The simpler the verb used, the better it is for the effectiveness of the function map.

Let us assume that the engineer working on the second-row door design has got the following from the target user about the challenge he faces with the current door design.

“As I try to close the door, I often get hit on my knee. Also, I often end up spoiling my seat with pulp juice because my 2.5L bottle does not stay upright”

The engineer understands that she needs to map out the components to understand how these problems are getting created in the first place. The Function Map is mapped out in the image below. All those interactions which, for this particular problem statement, has non-harmful functions or do not require improvements are denoted by the green arrows. Because we have a challenge at hand that the door handle (that is close to the human knee when the door is closed) is hitting the human leg, the red arrow is used to denote an interaction between the door handle and the human being. Also note that there are two arrows been used to denote the two different interactions that the door handle is having with the human being. The blue arrow denoting the action of holding the door handle by the human being, is because there is a scope of improvement in the way the human being is currently holding the door handle. The other blue arrow denoting the interaction between the human being and the bottle holder. This is because the bottle holder is currently not capable of holding bigger base bottles otherwise there is no need for the user to keep the bottle on the seat when there is a bottle holder.

The image below is a sample non-exhaustive function map – there are more component interactions that should be mapped out to complete the function map.

Since the design of the door handle is hurting the user, the engineer may decide to work on solving the issue. On the Function Map, the red Arrow depicting the interaction between the door handle and the human being thus becomes the ‘zone of concern’.

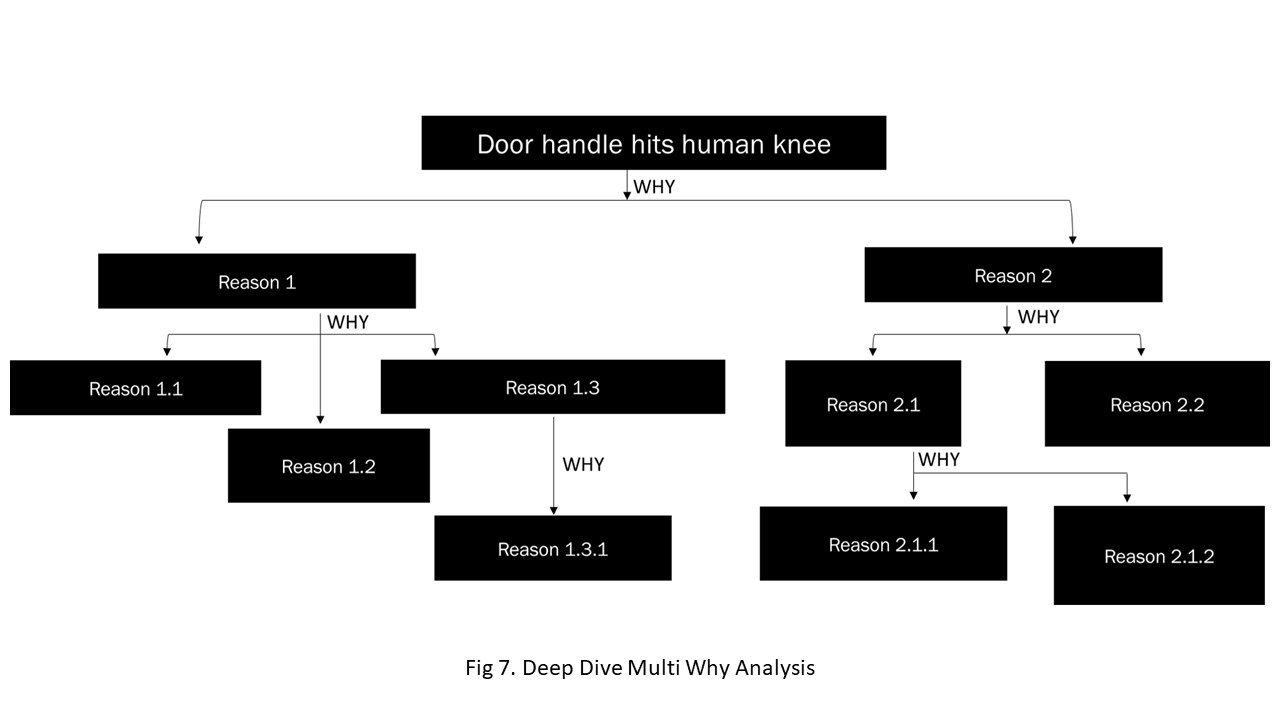

(c) Deep Diving

The third step in the design stage is Deep diving. The complete function map helps an engineer to identify the zone of concern which requires further investigation to identify the root cause off the challenge. To deep dive into the zone of concern, an engineer needs to ask WHY multiple times. Answers to those WHYs leads to uncovering layers of subtle insights. There can be multiple branches from a single node based on the multiple ways a WHY can be answered. How many WHY should be asked before an engineer decides the final challenge statement to work on? One should stop at the layer beyond which a solution demands the engineer to go beyond her domain. Typically, if you start with a well-defined problem, going beyond five WHYs is difficult. By the time we ask the third WHY itself, we will see a fresh insight emerging or one of our assumptions getting challenged.

A typical multi why analysis looks like this:

Here we continue on the door design challenge from where we left after the function map. The first block in the Deep Dive or Multi Why analysis should be the zone of concern. Typically, an actionable, strong insight surfaces by the third to fifth layer of the Deep dive. An engineer should decide on which insight to work on and create a one-liner challenge statement. This statement should start with the words ‘How Might We’ and should provide the engineer a clear technical challenge to solve.

For example, the engineer working on the design of the second-row door inner, might have found that the door handle is intentionally designed to protrude for easy access to the user but is hitting the knee of the user when trying to close the door. She may come up with her final technical challenge statement as, “How might we design the door handle in a way that it is easily accessible while the door is closed but does not interfere with any body parts while closing the door.”

Key Takeaways

By defining the How Might We statement, the engineer gets prepared for the next stage of design thinking which is ideation. Our paper focuses on (1) how to uncover the hidden insights using customer interviews and empathy exercises and (2) convert those insights into engineering problem statements to be solved. We have described the first stage of Empathy and the second stage of Define. We intend to publish a sequel to this paper, where we will discuss how to create the best possible solution that solves the challenge, how to build prototypes of the designed solution and how to validate the solution using those prototypes.

The automotive industry is showing trends similar to what the consumer electronics industry did a decade back. From core technical products to service experience, the industry is redefining what it offers to its end consumers. The evolution is fast happening and it is important for the new age engineers to catch up with this change. Designing with empathy is a skill that the mobility industry will greatly appreciate in their product design engineers. Practicing innovation methodology using Design Thinking principles is the best way an automotive engineer can embrace this change and establish herself as a coveted asset to the industry.

References

- Picturing how advanced technologies are reshaping mobility; Deloitte Insights; January 2019

- Nargess Banks; Jaguar Land Rover’s Project Vector Is an Exciting Flexible Smart City Transport Concept; Forbes Magazine; Feb 2020

- Steve Cropley; Jaguar Land Rover reveals secret autonomous Project Vector; Autocar Magazine UK; February 2020

- Oluwaseyi; How will electrification affect the way we design vehicles; Gravity Sketch Blog; April 2020

- Rasmus Hougaard, Jacqueline Carter, and Marissa Afton; Connect with Empathy, But Lead with Compassion; Harvard Business Review; December 2021

- Tim Brown; Design Thinking; Harvard Business Review Magazine; June 2008

- Clayton M. Christensen, Taddy Hall, Karen Dillon, and David S. Duncan; Know Your Customers’ “Jobs to Be Done”; Harvard Business Review Magazine; September 2016

- Valerie Alexander; How to Outsmart Your Own Unconscious Bias; TEDxPasadena; October 2018

- Tom Wujec; Got a wicked problem? First, tell me how you make toast; TEDGlobal; June 2013

- Thomas Wedell-Wedellsborg; Are You Solving the Right Problems?; Harvard Business Review Magazine; January–February 2017