An ecosystem approach for EV adoption

Countries have set timelines to reduce the manufacture of internal combustion engine (ICE) vehicles to meet targets specified in the Paris Agreement on climate change. But the share of electric vehicles (EVs) — the most practical replacement — was only 4% of global vehicle sales in 2020. [1] To accelerate adoption, EV makers need to amplify the network effect of other stakeholders in the mobility ecosystem.

Electric vehicles face serious barriers in the marketplace, in spite of regulatory and financial support from governments. Premium price, limited driving range, and the lack of charging infrastructure have all held back adoption. [2] A piecemeal solution isn’t likely to accelerate sales enough to meet ambitious national goals. An ecosystem approach is needed to drive EV adoption on a large scale. It amplifies the value offered beyond the manufacturer — a network effect of customers, charging stations, telecom and technology partners, and transportation providers across the ecosystem.

Perhaps the biggest challenge traditional automakers face for EVs is to offer something fresh to the market. As Sergio Marchionne, ex-CEO of Fiat Chrysler, warned in 2018 about electrification, “Carmakers have less than a decade to reinvent themselves or risk being commoditized.” [3]

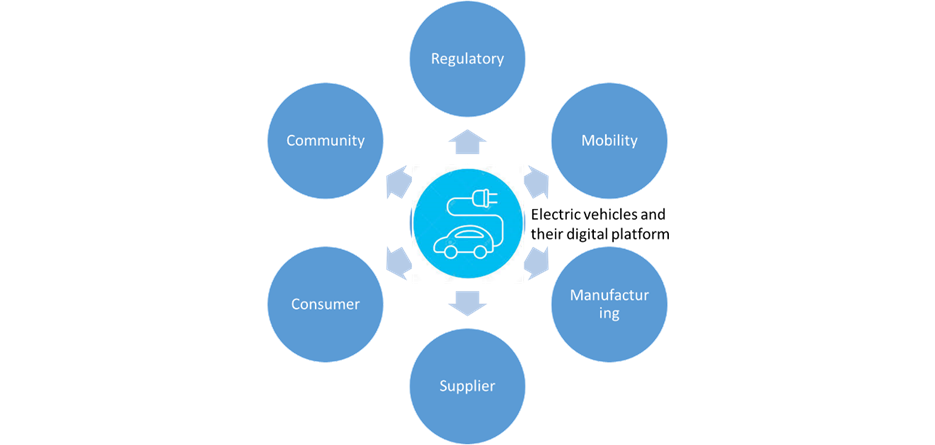

Vehicle and battery research will help achieve economies of scale. This addresses price performance, which is already trending downward. Vehicle makers need a compelling bundle of products and services, including digital technologies, to transport mobility beyond the internal combustion engine (ICE). To make this a reality, they need to think beyond EV design and manufacturing, and engage the entire EV ecosystem (Figure 1).

Figure 1. The EV ecosystem and its stakeholders

The predominantly digital EV ecosystem is different from gasoline or diesel vehicles. Connectivity is a basic requirement for EVs, and it addresses both comfort and so-called range anxiety. Drivers want to remotely monitor the charge in their vehicle to understand battery level and charging station proximity. Connectivity overlays vehicle location information with the remaining charge to locate the nearest charging point. EVs also have advanced remote access features, such as vehicle lock, unlock, and anti-theft alarms, that need connectivity.

These features have created a unique digital environment for EVs. Gartner defines this digital ecosystem as an interdependent group of enterprises, people, and things that standardize digital platforms for mutual benefit. In this case, the EV ecosystem has the potential to benefit from an indirect network effect. EV adoption is positively influenced by the growth of vehicle connectivity, new business models, manufacturing practices, and sustainability in the automotive sector.

To achieve global and national EV targets, automakers need to act quickly, particularly when so many stakeholders want the car companies to succeed and governments have shown a willingness to subsidize EVs on a large scale. The World Economic Forum (WEF) considers 2020 as the tipping point in the sale of EVs, despite their market share still being under 5%. [4] Sales are trending upward, with about 2.3 million EVs sold in 2020, nearly four times the number in 2015.

The automotive industry continues to invest heavily in EVs, taking the lead from governments and policymakers, with the assumption that EVs are the future of passenger vehicles. Volkswagen, for example, announced in late 2020 that it planned to spend 73 billion euros ($86 billion) on digital and EV technologies over the next five years. [5] Nearly half of its investment budget would be allocated to e-mobility and associated areas such as autonomous driving features and embedded software.

EV ecosystem use cases

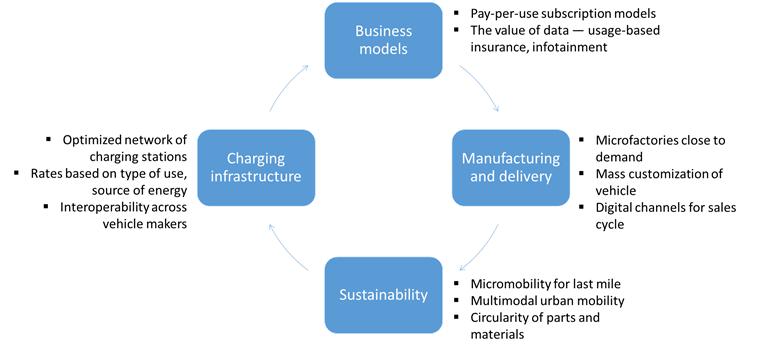

There are four major areas where an EV ecosystem can support innovation: business models, manufacturing and delivery, charging infrastructure, and sustainability (Figure 2). These four categories holistically address how EVs are made, how the EV makers make money, how customers operate EVs, and how these vehicles are handled in an environmentally friendly way at the end of their life.

Specific use cases are identified under each of these broad categories. Each of them has the potential to become a profitable and long-term business of its own. Digital technologies are a common thread to implement each of these use cases.

Figure 2. Innovative use cases to address EV challenges and opportunities

Business models

Carmakers need to transform their business models to make EVs affordable, and new business models can be beneficial for manufacturers, customers, and other ecosystem players. Vehicle manufacturers gain access to new revenue streams. Customers benefit from decreased cost to drive and lower insurance premiums by practicing safe, responsible driving habits. Here are two examples:

- Pay-per-use model — A recent Infosys study on subscription models shows that nearly three-quarters of automotive manufacturers earn less than 5% of their annual revenue from subscription-based business. The one-time sale of new cars continues to be their primary revenue stream. But subscription models are an opportunity to serve customer segments not interested in a long-term investment or priced out of the EV market. Many prefer flexibility and choice for cars and payments. Today, automotive original equipment manufacturer (OEMs) follow a flat monthly fee model. Instead, the fee can be based on the actual distance driven each month and driving patterns by leveraging internet of things connectivity. OEMs need cost models that identify per-mile charges and consider all direct and indirect costs.

- Power of data — The connected nature of EVs lets carmakers measure driver behavior objectively and analyze driving patterns. Speeding and harsh braking are variables that can be analyzed to arrive at a driver’s risk score. That score can be used to adjust the cost of an insurance premium, incentivizing safe and responsible driving. This practice mitigates risk for both vehicle makers and insurance providers. In a competitive market, the benefits would eventually be passed on to customers in the form of a lower subscription fee and insurance premium. The lack of industry standards for driver behavior is also an opportunity to shape the future. Training applications using simulators and immersive virtual reality can influence potentially unique EV driving styles. Examples include less braking and more gradual deceleration to help regenerative braking. EV drivers get comfortable with these habits in a simulated environment before exhibiting them in an actual vehicle on an actual road.

Manufacturing to customer needs

EV manufacturers enjoyed subsidized, lower barriers to market entry, but their products still cost more than comparable ICE vehicles. They face an imperative to quickly evolve due to market turbulence. [6] Turbulence is the degree of uncertainty, instability, and the lack of control in markets. It can be measured by factors such as globalization, product life cycles, technological change, and changing customer preference. EVs are at such a stage of becoming commoditized today. Customer preferences are undergoing changes toward flexibility in product choice and payment options. There is competition from multiple EV manufacturers. Manufacturing provides an opportunity to differentiate the products while keeping cost under control and to address the commoditization challenge.

There are three changes that can speed up the manufacturing process, make EVs cheaper, and better meet customer needs.

- Microfactories — Two decades ago, the Mechanical Engineering Laboratory in Japan introduced the concept of a microfactory: a small- to medium-scale, highly automated, and technologically advanced manufacturing facility. EV manufacturing lends itself to microfactories and the use of hyper automation due to vehicles’ modularity and smaller part count. Tesla, for example, says its drivetrain has 17 moving parts compared with more than 200 on an ICE vehicle. This could allow carmakers to reduce logistics expenses by manufacturing EVs closer to the point of demand. Logistics costs are big business; U.S. logistics accounted for 7.6% of the country’s gross domestic product in 2019, according to the Council of Supply Chain Management Professionals. To combat this, in 2020, EV firm Arrival announced plans to set up a U.S. microfactory with cell-based manufacturing instead of a traditional assembly line.

- Mass customization of vehicles — EVs face a high risk of commoditization. Popularized by Columbia University professor and author Joseph Pine in his book “Mass Customization: The New Frontier in Business Competition,” mass customization addresses this challenge by tailoring some aspects of a scaled manufactured product according to customer-specific preferences.6 OEMs such as Volkswagen develop EVs based on a modular architecture to promote interchangeability of parts between vehicle models. Modularity of key parts at an OEM level or — even better — at an industry level, supports mass customization.

- Digital channels for the sales cycle — The need for social distancing during the COVID-19 pandemic has encouraged the growth of digital channels in the automotive sales cycle. While it can weaken the dealer relationship, digital channels create closer OEM-customer relationships and provide more opportunities for mass customization. The direct-to-customer model adopted by Tesla and other OEMs has accelerated the online car market that bypasses the traditional dealer channel.

Charging infrastructure

Charging infrastructure is the lifeline of EVs. Governments and business need to spend $500 billion by 2040 to deploy an additional 290 million charging points, according to the WEF. [7] That is 20% compounded annual growth from the 7.9 million chargers available globally in 2019, according to the International Energy Agency. [8] Governments offer incentives to set up charging stations, but the following steps can be taken to make them profitable, sustainable, and self-sufficient.

- Business models — Charging stations can be vendor or customer owned, or a hybrid model of both. Battery swapping is also an option, especially in developing countries with unreliable electric grids. Drivers can rent a battery at one charging station and return it to another, with usage and location accurately tracked. Also, digital advertisements can be streamed to the driver and passengers either at a charging station or on the vehicle’s infotainment system.

- Charging network — It is not only the number of charging stations that is critical, but also their location, type of energy used, and time needed to charge. The network can be optimized to minimize charging time for EV owners, modeling each station as a queueing system.

- Interoperability — Each OEM can produce a proprietary charger, or they can collaborate to create an industrywide vehicle standard. The second option should result in high charging station utilization, which is anticipated to continue as a bottleneck for EV adoption.

- Usage —The International Renewable Energy Agency reported a low share of renewable energy used in transportation globally: 3% in 2016. [9] EVs play a key role in increasing this share of renewable energy for mobility. Bidirectional flow between the grid and charging stations, as well as dynamic pricing based on the time of day, will improve load balancing and potentially generate new profit streams. Dynamic pricing minimizes queues for charging during peak hours, incentivizing drivers to choose off-peak, less expensive times.

Sustainability

EV makers have an opportunity to design for sustainability, not as an afterthought. Neodymium and dysprosium, for example, are rare metals used to make magnets for the electric motors in EVs. Lithium and cobalt — only available in limited regions — are required for vehicle batteries. Extraction is expensive and environmentally damaging, and these costs and risks should be factored into financial models.

- Circularity — The rare, valuable materials used to make EVs can be recycled and reused. Circularity in the automotive industry could reduce carbon emissions up to 75% and resource consumption up to 80% per passenger kilometer by 2030, according to the World Business Council for Sustainable Development. [10] EV makers should think beyond circularity for usage of common, nonvirgin materials to make EVs a sustainable and green mode of mobility. Unlike ICE vehicles, the EV market is new and has a small base. This provides the opportunity to introduce circularity from the start — not just for social responsibility but to reuse valuable materials and save cost.

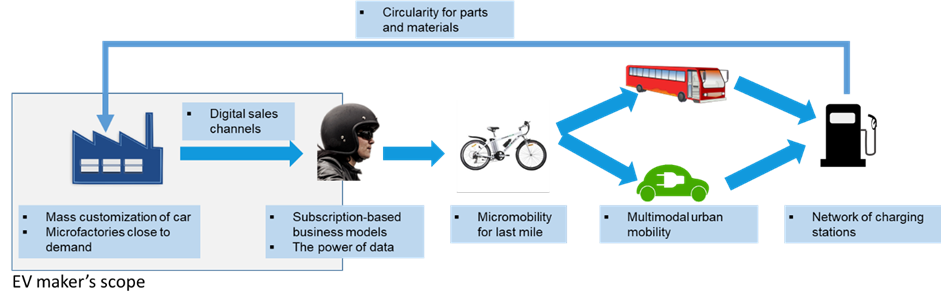

- Multimodal transportation — EV makers need to determine how their vehicles compare against and align with other modes of transportation, particularly in dense urban areas (Figure 3). An ideal situation is EV integrated into “mobility as a service” (MaaS). The United Nations Economic Commission for Europe describes MaaS as a way to enable end-to-end trips with multiple transport modes. It is provided by different service providers under a single platform for trip planning, scheduling, ticketing, and payment. Sustainability is a key aspect of MaaS. EVs lend themselves well to MaaS, specifically the last mile for users, because of their zero emissions and frugal usage of natural resources to make and operate them.

- Micromobility — The Institute for Transportation and Development Policy describes micromobility as a range of small, lightweight devices operating at speeds typically below 25 kilometers per hour (15 miles per hour). These vehicles, which are usually electric bikes or single-passenger cars, are ideal for trips of up to 10 miles. Among all trips in the U.S, 80% are less than 12 miles. Micromobility with EVs is the ideal mode of travel for such short distances. Micromobility is the future of urban transportation, according to the WEF. [11]

Figure 3. An ecosystem approach across the life cycle of an EV

An EV ecosystem mindset ensures thinking beyond the product features to the way customers will actually use them. It will not be feasible for EV makers to implement every facet in the vast ecosystem required for large-scale, sustainable operations. However, EV makers that involve all stakeholders in the ecosystem from the early stages will greatly benefit. For consumers, an ecosystem approach addresses range anxiety and offers them affordable payment options. For service providers, it enables new revenue opportunities such as reverse logistics for circularity, usage-based insurance, and charging station operation. Automotive firms can focus on their core competencies, while partners develop the rest of the required capabilities. Ecosystem growth is a way to not only ensure EV adoption but also to develop business opportunities beyond their one-time sale.

References:

1 – How global electric car sales defied Covid-19 in 2020, Marine Gorner, Leonardo Paoli, January 28, 2021, International Energy Agency

2 – Electric vehicles for smarter cities: The future of energy and mobility, January 2018, World Economic Forum

3 – Fiat Chrysler’s Marchionne: The Future of Cars Will Be Electric and Commoditized, Tommaso Ebhardt

January 15, 2018, Bloomberg

4 – 2020 was a breakthrough year for electric vehicles. Here’s why, Douglas Broom, January 20, 2021, World Economic Forum

5 – VW boosts investment in electric and autonomous car technology to $86 billon, November 13, 2020, Reuters

6 – Mass Customization: The New Frontier in Business Competition, Joseph Pine, May 1993, Harvard Business School Press

7 – Here’s how electric vehicles can keep us on the road to Paris, Jonathan Eckart, Frank Muehlon, September 11, 2020, World Economic Forum

8 – Global EV outlook 2020, June, 2020, Technology report, International Energy Agency

9 – Electric Vehicles: how smartly should we charge them?, January 21, 2020, International Renewable Energy Agency, #IRENA insights webinar series

10 – Raising Ambitions: A new roadmap for the automotive circular economy, December, 2020, World Economic Forum, World Business Council for Sustainable Development and Accenture

11 – Why your next car is a bike, Carlo Ratti, Ida Auken, November 14, 2019, World Economic Forum

Ramachandran S (Ram) is a Principal Consultant in the thought leadership team Infosys Knowledge Institute. He is the lead for manufacturing and engineering. His current areas of interest are Industry 4.0, servitization and circular economy. He has co-authored a book ‘Neoskilling for Digital Transformation’ along with Prof L Prasad, IIM Bangalore (Wiley India, 1991). Ram has co-authored a chapter on Servitization in an upcoming book on Advances in digital manufacturing systems. He is a frequent speaker and blogger on these topics.

Good article!