Multiphysics Simulation for Enhanced Electric Drivetrain Efficiency

- Home

- >

- Multiphysics Simulation for Enhanced Electric Drivetrain Efficiency

Multiphysics Simulation for Enhanced Electric Drivetrain Efficiency

Abstract

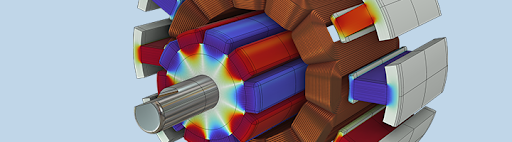

The performance of EVs is largely dependent on the performance of the electric drivetrain. Improving the efficiency of the drivetrain involves addressing an interplay of different physics phenomena, such as electromagnetics, vibrations, heat transfer, and solid mechanics. Multiphysics simulation plays a crucial role in modeling such phenomena and enabling an agile process for the R&D of electric drivetrain components.

Join us for this live webinar to learn about using modeling and simulation to improve electric drivetrain efficiency. This webinar will include live demonstrations and a Q&A session.

We will cover:

- - Modeling permanent magnet motors, induction motors, and linear motors

- - Combining different physical effects to model phenomena such as structural stresses, rotor-induced vibrations, noise emission, and temperature rise due to power dissipation

- - Examining and optimizing parameters influencing motor efficiency, such as rotor torque as well as iron and copper losses, including the effects of temperature rise

- - Topology, parameter, and shape optimization for improving electric motor designs

Permanent Magnet Motor in 3D

Speaker: Mr. Prawal Jain, Applications Engineer, COMSOL

Speaker: Sharath B. N. Technical Specialist, COMSOL

Speaker Bio: Sharath received his master’s degree in machine design from BMS college of engineering in Bengaluru. Before joining COMSOL, he worked on mechanical integrity assessments of Siemens gas turbines in Tata Consultancy Services.